Wir sind für Sie da. Digital und persönlich.

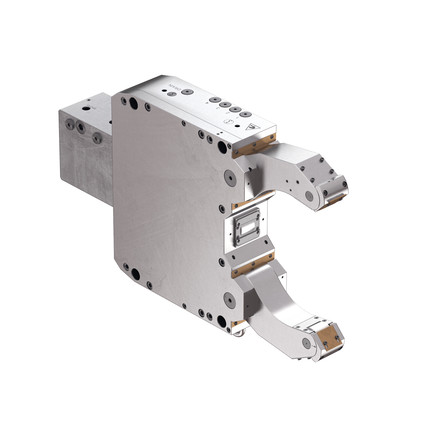

Wir beraten Sie - wo immer Sie sind

Unsere Mitarbeiter in Vertrieb und Service sind für Sie da. Telefonisch, per Video, per E-Mail.

Mit einem Klick per E-Mail:

sales@roehm.biz

service@roehm.biz

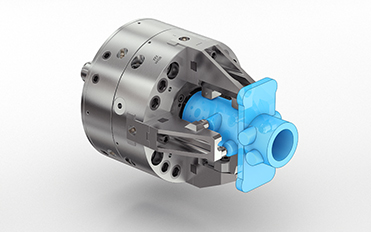

Röhm Produkte online kaufen

In unserem eShop sind wir 24/7/365 für Sie da.

Versandkostenfrei ab 150 EUR.

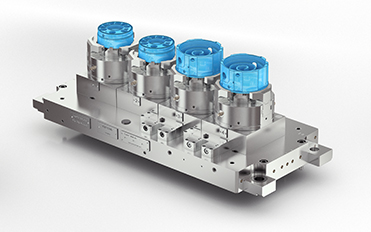

CAD Daten

In allen gängen Formaten (DWG, DXG, IGES, STEP, uvwm.) herunterladen

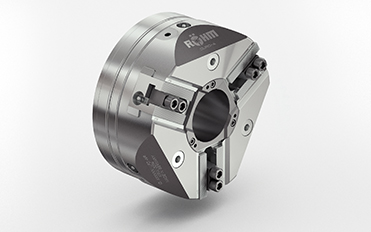

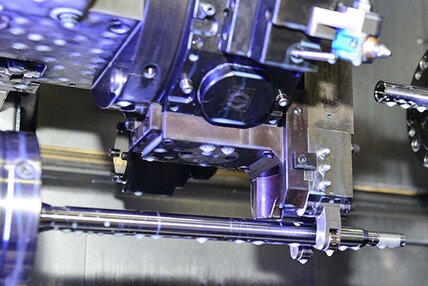

Spannbacken online finden

Hier finden Sie die richtige Spannbacke für Ihr Drehfutter (auch Schunk, SMW, Forkardt, Bison).