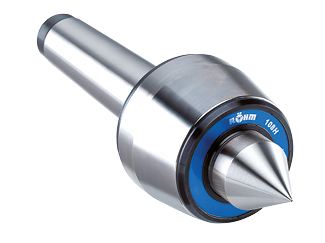

Live centers

For counter-clamping workpieces on turning and grinding machines with max. 0.005 mm concentricity deviation

The requirement for high cutting capacities and high working precision demands additional support by a live center for many workpieces due to their shape and length. Thanks to their precision bearings, RÖHM live centers offer optimal force absorption and a maximum concentricity deviation of up to 0.005 mm. The center points are maintenance-free thanks to the lifetime lubrication.

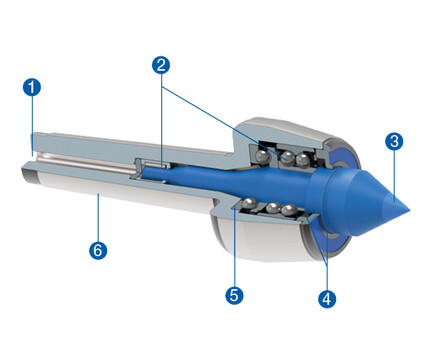

1: Shank hole for easy exchange of the center point

2: Precision roller and needle bearings for maximum concentricity with long service life

3: Center point with wear-resistant, hard-metal insert, can be reground multiple times, and shank mounted

4: Lip seal and additional water spray groove as protection against penetration of cooling lubricants

5: Solid supporting surface on the axial bearing for full loading capacity

6: Ground shank, true to gauge according to DIN 228 AT5 for tight tolerance and maximum concentricity

Pro-Series

“the Röhm center”: the center that (almost) always fits.

Heavy series

for particularly heavy workpieces or high loads at high speeds with an extended center point

Speed series

for very high speeds with an extended center point, up to MK5, up to 12,000 rpm

Slim series

for tight working space between the point and workpiece

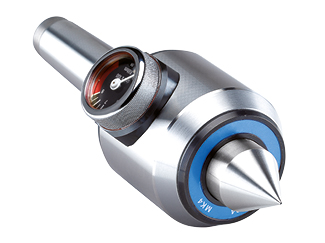

Control series

for adjusting and checking the axial load, optimally suited for machining with face drivers

Flex series

for a broad range of applications with interchangeable inserts