iJaw benefits

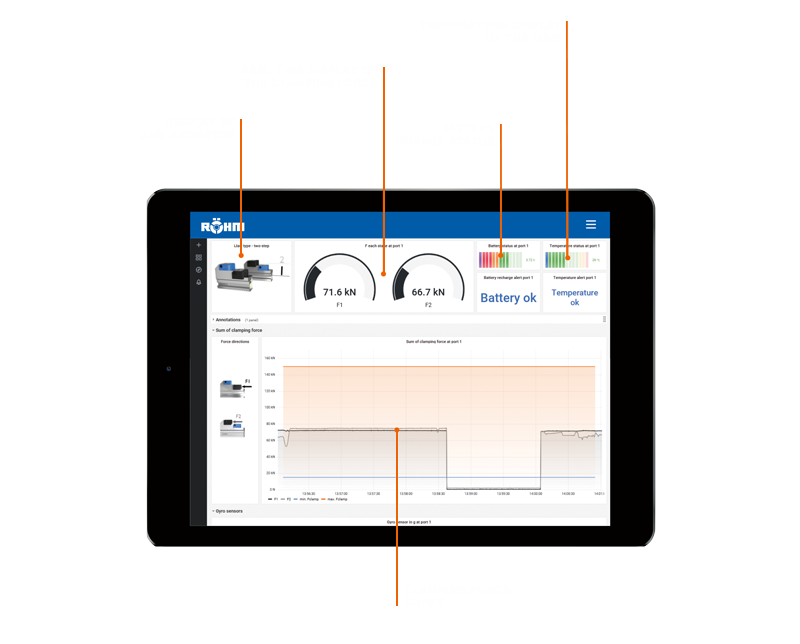

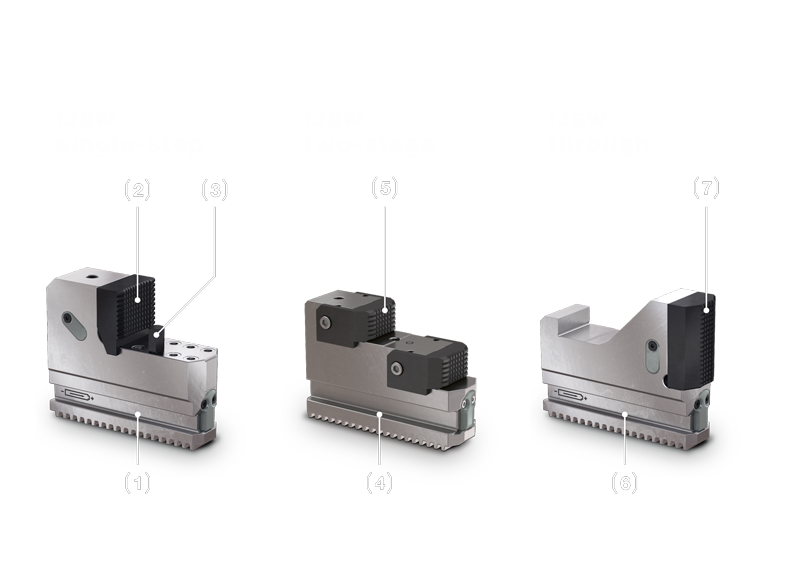

Machine tools can be retrofitted very easily with the iJaw. All you need are the sensorized clamping jaws, the gateway, an industrial PC and a medium for visualizing the measured data. This can be a local PC or a mobile tablet.

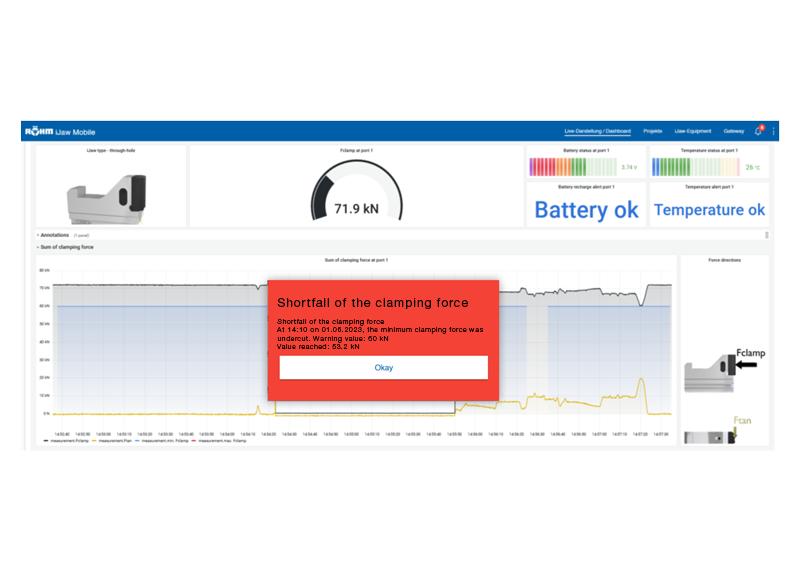

The system is controlled by the iJaw Mobile web app. With this application, you establish the connection between the iJaw and the gateway so that you can retrieve the data.

You can create jobs, manage your jaws and receive warnings via software, e.g. if the minimum clamping force has not been reached.

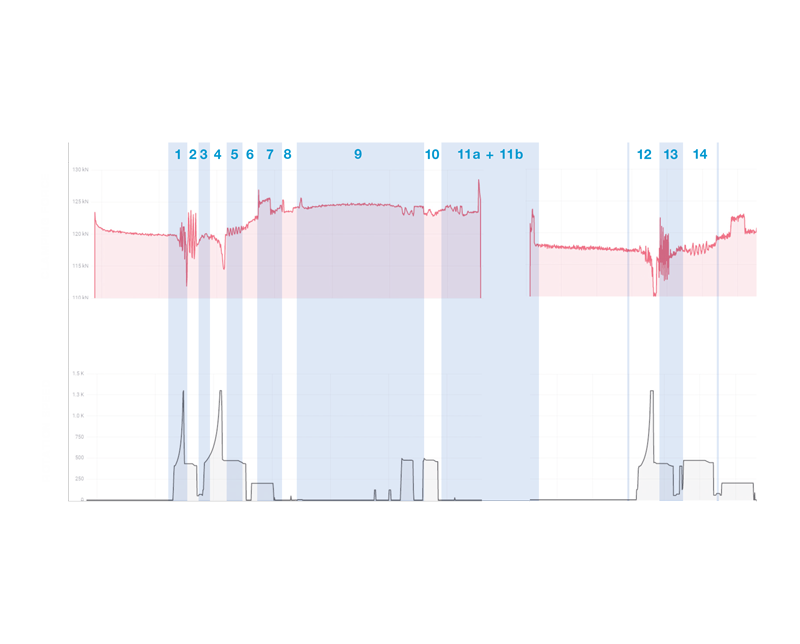

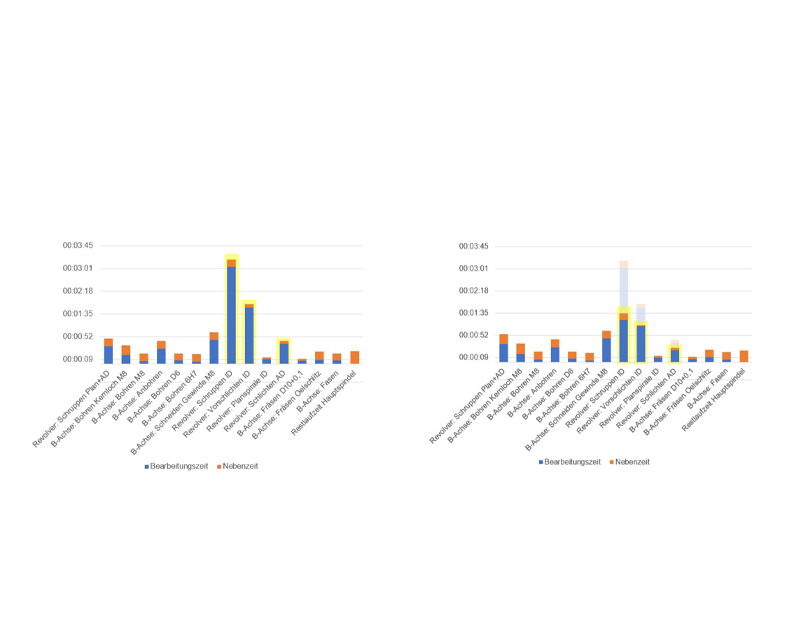

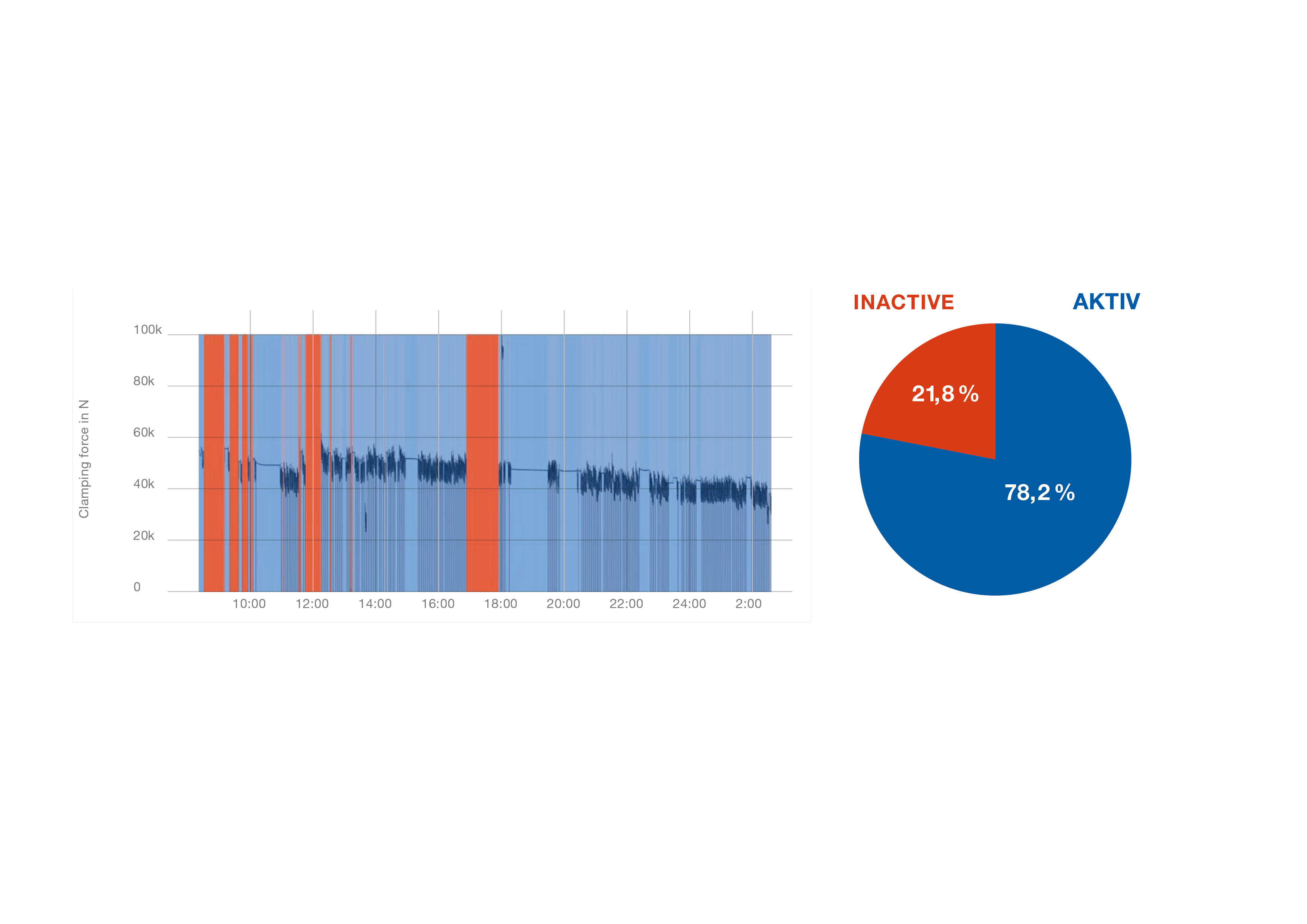

Optionally, you can connect your system to the cloud*. It enables additional functions such as process or productivity analyses over longer periods of time and the documentation of large amounts of measurement data. With the iJaw Mobile app, you can access your data from anywhere and evaluate processing data or have warning messages displayed.

*Cloud functions not yet available

Basic function

- Measurement of the clamping forces of internal and external clamping at standstill and under rotation

- Display of minimum and maximum clamping force

- Alarm when clamping force is exceeded or not reached

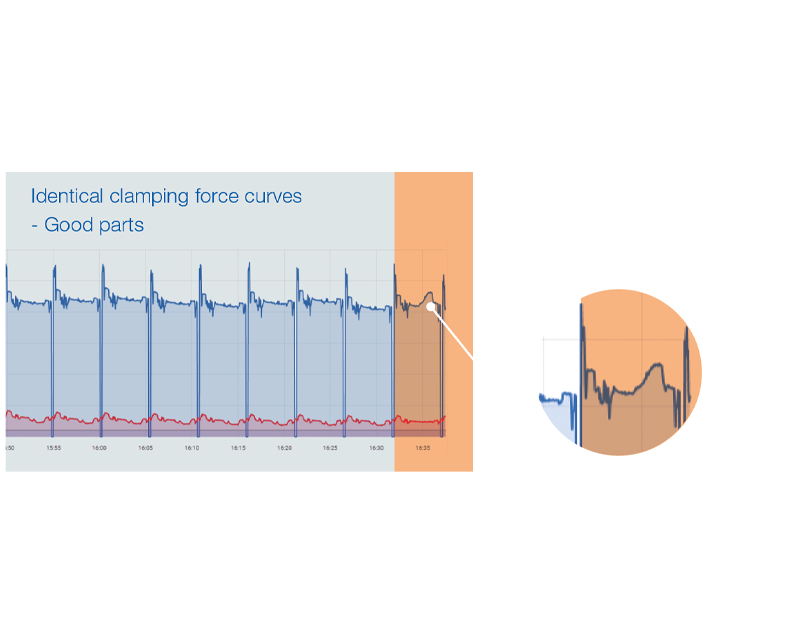

- Display of the clamping force curve

- Temperature of the iJaw

- Charging status of the battery