Segment clamping mandrels

For force-actuated, precision, internal clamping for turning, milling, grinding and gear cutting with quick-change system and long sleeve elongation

Modern manufacturing engineering can hardly do without using segment clamping mandrels. In the areas of finishing, turning, grinding, gear cutting and sensing, segment clamping mandrels take on important tasks associated with lofty conditions. The spaces between the segments of the mandrel are filled with an elastic vulcanized material. This enables a great deal of elongation up to 1.2 mm thereby making it easier to load the workpiece in the mandrel. At the same time, the elements ensure damping of vibrations. The segments themselves are made of hardened and polished steel for high wear resistance and accuracy.

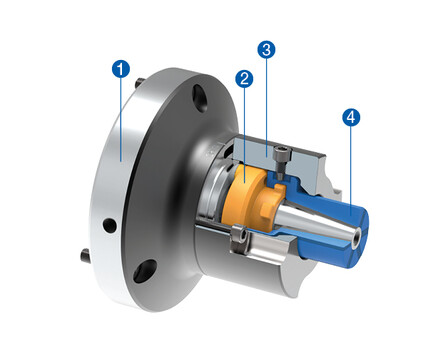

1: Low weight and reduced overall height due to compact construction

2: Patented quick-change system for quick change of the segment sleeves and workpiece stop

3: Workpiece stop with prepared air sensing

4: Segment sleeve with innovative, vulcanized material for large elongation, longest service life and vibration damping

ABSIS

Force-actuated, internal clamping with axial tightening for long clamping lengths of round workpieces for turning, milling, grinding and gear cutting as well as balancing and measuring. Ideal for clamping in through-holes.

Clamping range: Ø 19.7 – 107

AGILIS

Force-actuated, internal clamping with axial tightening for short clamping lengths of round workpieces for turning, milling, grinding and gear cutting as well as balancing and measuring. Optimally suited for very small clamping diameters as of 10 mm.