To increase productivity, many manufacturing companies are continuously looking for ways to better utilize their machines. This is particularly important now, with the increase in demand for manufacturing of individual parts and small batches. Zero point clamping systems are particularly well suited for this environment to drastically shortening ineffective idle times of machines and systems. They connect workpieces, vices, pallets or devices with the machine table precisely and within seconds. Since multiple pallets can be equipped outside the machine during the machining time, the machine spindle utilization is extended significantly. This achieves up to 90% in set-up time reduction

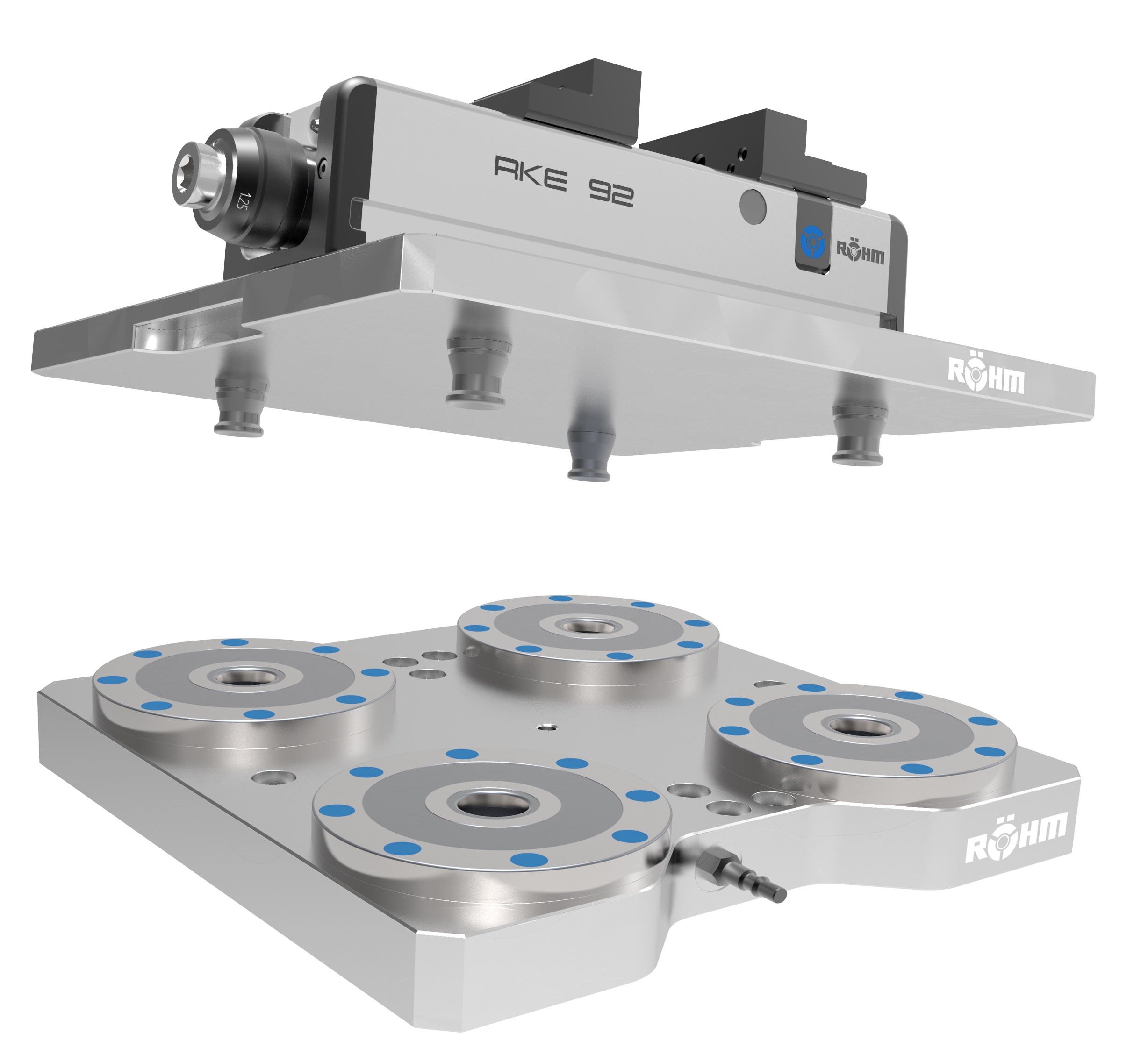

Röhm, the clamping and gripping specialist from Sontheim, Germany, has been highly competent in zero point clamping systems for many years. The current products include the Easylock zero point clamping system. With this improved solution, the draw bolt system serves as a precision interface between the pallet carrier and the receiver unit. The pallet carrier can be fitted with vises, stationary lathe chucks, collet chucks and customized fixturing solutions. The benefit of our Easylock system is the outstanding repeatability of less than 5 µm.

A practical example would be: the set-up operator has to set up a new job on a vertical machining center. The preparation needed to set-up the job could take as long as 2 hours if you consider all the steps needed to accomplish this: tearing down old set-up, cleaning the table and T-slots, stoning the table to remove nicks and burrs, retrieve new workholding, determine new layout, use a dial indicator, finish the alignment, enter fixture offsets into CNC control, enter the program, clamp the workpiece, bring the tool to proper Z-position and carefully step through cuts. By utilizing the Easylock zero point clamping system, all these wasteful steps are eliminated. This method maintains an established zero point, ensures considerably shorter set-up times for the machine, and is completely automation-ready.

As a system supplier, Röhm offers palletizing as well as clamping devices from a single source. The Easylock zero point clamping system can be actuated pneumatically or hydraulically. The prefabricated pallets can be combined in a modular system with a multitude of standard clamping devices. Different sizes with diameters between 62 and 138 mm are available. All clamping units consist of stainless steel; the receiver carrier and pallets are designed with high-strength aluminium. The system is very well suited for manufacturing processes such as milling, grinding or drilling as well as for measurement-related processes.