(Schaffhausen/Sontheim) The production of the main plate marks the birth of a manufacture caliber, the heart of high-precision, mechanical luxury watches. IWC Schaffhausen uses a KERN Micro for reliable and repeatable production. The award-winning swivel chuck from Röhm's micro-technology series is mounted on it. This enables IWC to achieve maximum precision and repeatability in a single clamping process with dozens of machining steps and countless tool changes. We took a very close look.

We look into a production hall that at first glance looks like many others, were it not for the numerous red Kern machines that promise something special. It would not have been possible for us to enter here at all without an escort. No company sign, nowhere the familiar IWC logo, nothing to indicate the manufacturer of luxury watches. When Christian Indlekofer, production manager for movement parts at IWC Schaffhausen, tells us that the most valuable IWC watch costs 750,000 Swiss francs; we are deeply impressed and can certainly understand the secrecy.

The manufacture of the plate marks the birth of a movement

Nevertheless, today the manufacture of components for calibers, as watch manufacturers call their own specially developed, manufactured, and assembled movements, is only possible with state-of-the-art CNC-controlled precision machines and machining centers. This does not change the value of the watches — on the contrary: in addition to high-quality materials, design, and complications (the name given to functions such as date, second time zone, or annual calendar) in a valuable wristwatch, customers also expect maximum accuracy. "The process-reliable and repeatable manufacture of individual parts is only possible by machine. Assembly, on the other hand, continues to be done by hand according to old tradition," explains Heiko Zimmermann, who is responsible for industrialization.

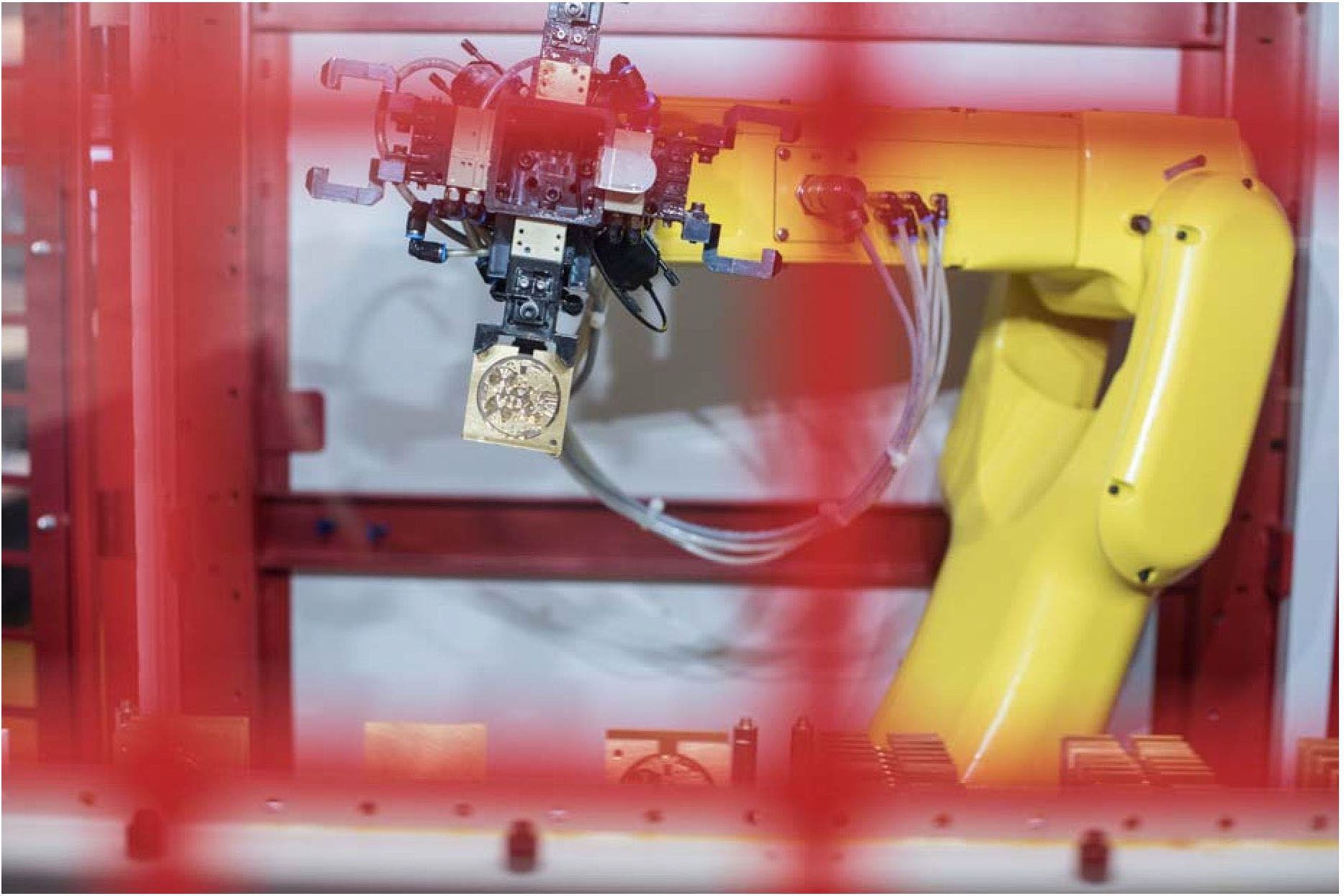

So now we stand in front of a KERN Micro, a very compact precision machining center, and watch as the handling robot inserts a brass plate measuring 50 x 50 x 3.25 mm. Stephan Zeller, Regional Sales Manager at Kern, immediately describes what makes it so special: “With the KERN Micro, IWC has a very compact 5-axis machining center with a footprint of only four square meters that is highly automatable and works with precision down to the nano range.” This is guaranteed, among other things, by the temperature control of all heat-generating components in the machine. With 101 tools in the easily accessible tool cabinet, which can even hold a maximum of 209 tools, all process steps are covered.

Award-winning swivel chuck from Röhm

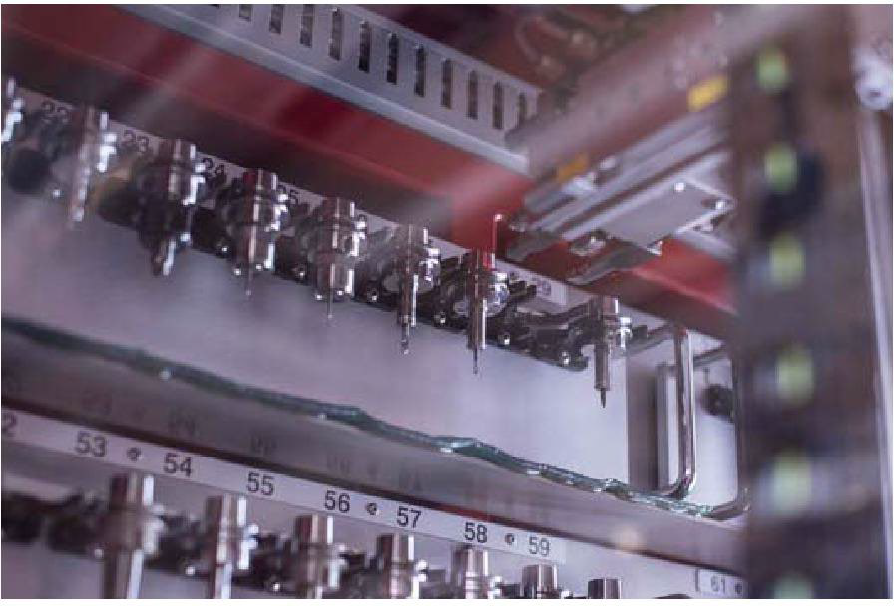

The award-winning power clamping swivel chuck from Röhm's micro-technology series is installed in the tidy workroom. With this globally unique chuck, which was conceived by Röhm in Switzerland and constructed at its branch plant in Dillingen, IWC can perform all necessary operations on the plate in a single clamping process. These include milling, drilling, thread cutting, and grooving, as well as fine machining of the edges. Even the hole for the winding shaft, which runs horizontally from the outer edge of the plate to its center, can be drilled without re-clamping. “We used to have to clamp the plate onto three machines,” recalls Zimmermann. Of course, this took longer overall and carried the risk that the result could be less precise than it is today. After measuring the workpiece, taking into account the tolerances of the blank, the system sets its zero point.

270 processes with 54 tool changes on 0.001256637 m2

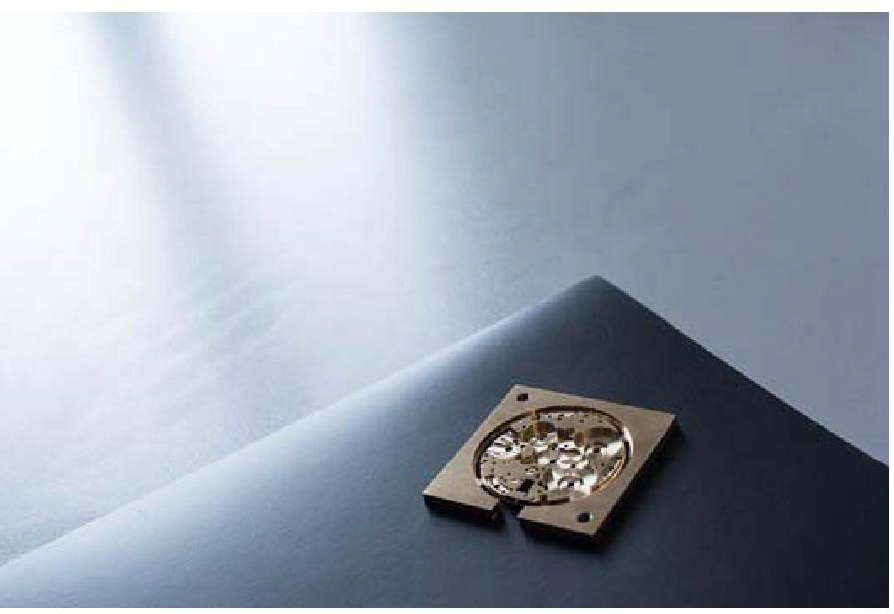

The watch plate is the central component of a mechanical watch. All components of the movement are later placed on it, from the bridge and balance cock to the ruby jewels, pins, axles, and gears. Depending on the complication, such a movement can consist of several hundred tiny parts. Before the chuck releases the blank as a finished plate for removal, an incredible 270 operations with a total of 54 tool changes are performed on the movement side and the dial side with the KERN Micro, with a precision of +/- 2 pm. Each tool is used only once. The machining steps and their sequence are planned very precisely. BECAUSE the swivel chuck turns the plate faster than a tool change can be performed, operations are always carried out on both sides of the plate with one tool before it is changed.

This creates holes in the watch plate, which will later measure 40 mm in diameter, with the smallest holes measuring just 0.38 mm in diameter, threaded holes, and space for the movement components. In some places, the material of the blank is removed down to 0.5 mm. This, in turn, poses a very special challenge for the chuck. Under no circumstances should the brass workpiece bend or even break under the force exerted on it. The force exerted should not be underestimated, especially during grooving processes. Bending would lead to inaccurate results. Therefore, a workpiece support, a kind of stop, is required.

Support that works on both sides

But this is not so easy, because the support that holds the plate from below and prevents it from bending must continue to work from below after it has been swiveled. Röhm has found a clever solution that is unique worldwide. “A pneumatically operated clamping yoke rotates 180° after the chuck has been swiveled, thus supporting the workpiece from below again,” explains Damiano Casafina, Managing Director of Röhm Switzerland, who came up with this innovative and simple solution.

Nevertheless, the difficulty here also lies in the details. After the clamping yoke has rotated, it must not strike the plate with full force. This could bend or destroy the plate or cause it to be ejected from the clamping jaws. Röhm has therefore installed a kind of brake that gently guides the support onto both sides of the plate from below, locks into place, and performs its supporting function. This allows processing to be carried out with the necessary precision in all processes.

Casafina refuses to reveal how this mechanism works in detail. “That is and remains our know-how, of course.”

Further increasing flexibility and productivity

The combination of KERN Micro and Röhm's swiveling power chuck has been in use since October 2015. “The unit now produces 140 hours per week,” Zimmermann reports with pride. Thousands of plates are to be manufactured on it within a year, with process reliability and repeat accuracy. And the next step is already planned, as Indlekofer announces: “Above all, we want to further increase flexibility, but also productivity.” A 4-fold chuck with swivel function is being considered for this purpose. Kern and Röhm are already working on the jointly agreed plan. And so Zeller and Casafina emphasize in unison, “that only the close coordination between us and the good cooperation has brought these pleasing results for the customer IWC.” We will be happy to see this for ourselves again on our next visit to the secret location.

About Röhm GmbH:

Röhm GmbH, with its headquarters in Sontheim an der Brenz (Baden-Württemberg) and production sites in Dillingen (Bavaria) and St. Georgen (Black Forest), specializes in the development, design, and manufacture of high-precision, robust and durable clamping and gripping devices. The products are "Made in Germany" Röhm's clamping and gripping devices are used worldwide by almost all renowned manufacturers in the automotive industry, railroad technology, watches, medical technology, power engineering as well as in woodworking. Röhm also manufactures special clamping devices and handling equipment for use in cleanrooms in accordance with cleanroom class ISO 7.

Röhm has its own subsidiaries in England, France, Italy, Switzerland, Spain, Poland, USA, China, and Mexico. Founded in 1909, the company quickly became known worldwide for its drill chucks. To this day, Röhm develops and manufactures drill chucks at the Sontheim location that are used worldwide by almost all manufacturers on stationary as well as hand-operated electric tools for screwing and drilling.

www.roehm.biz