Press

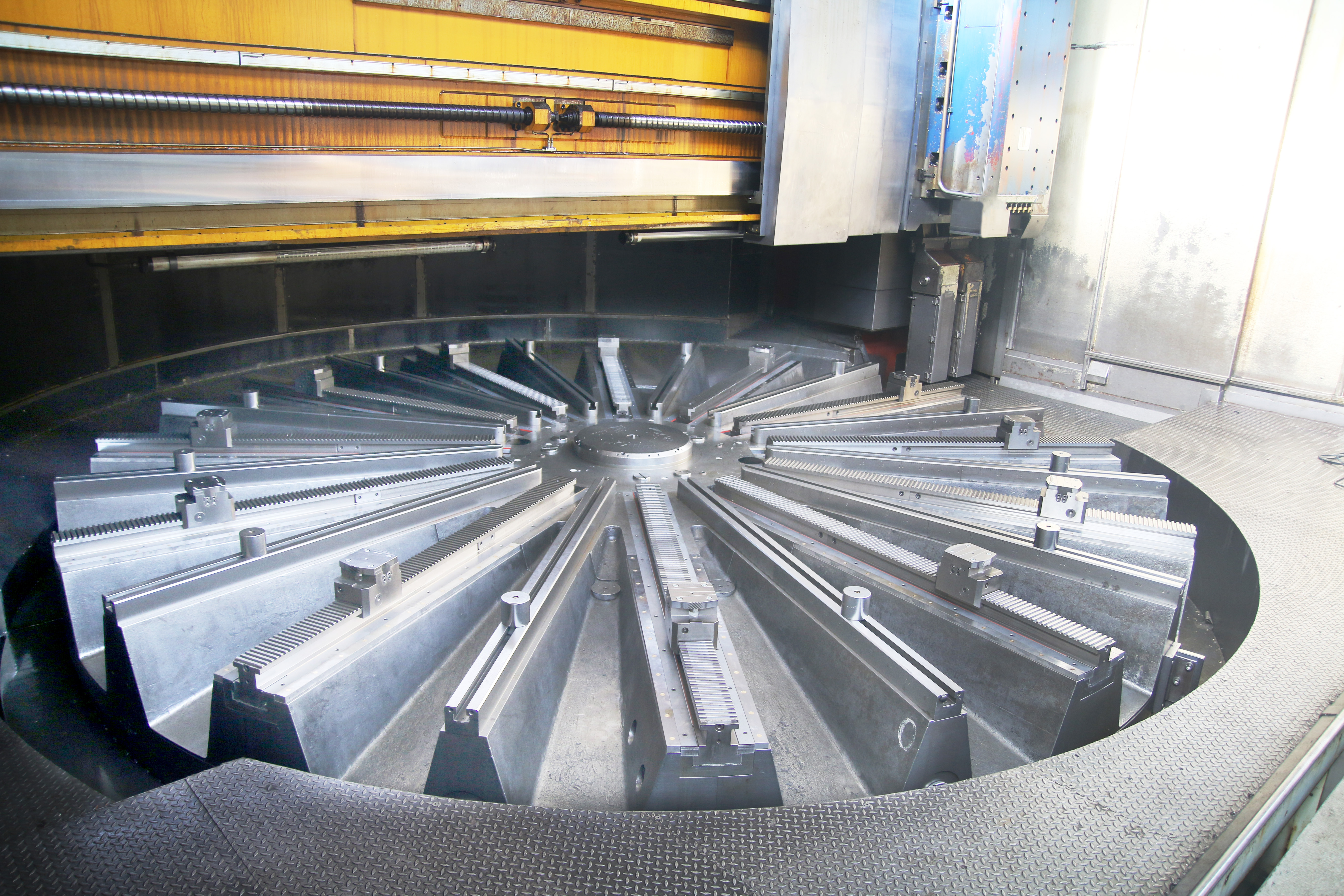

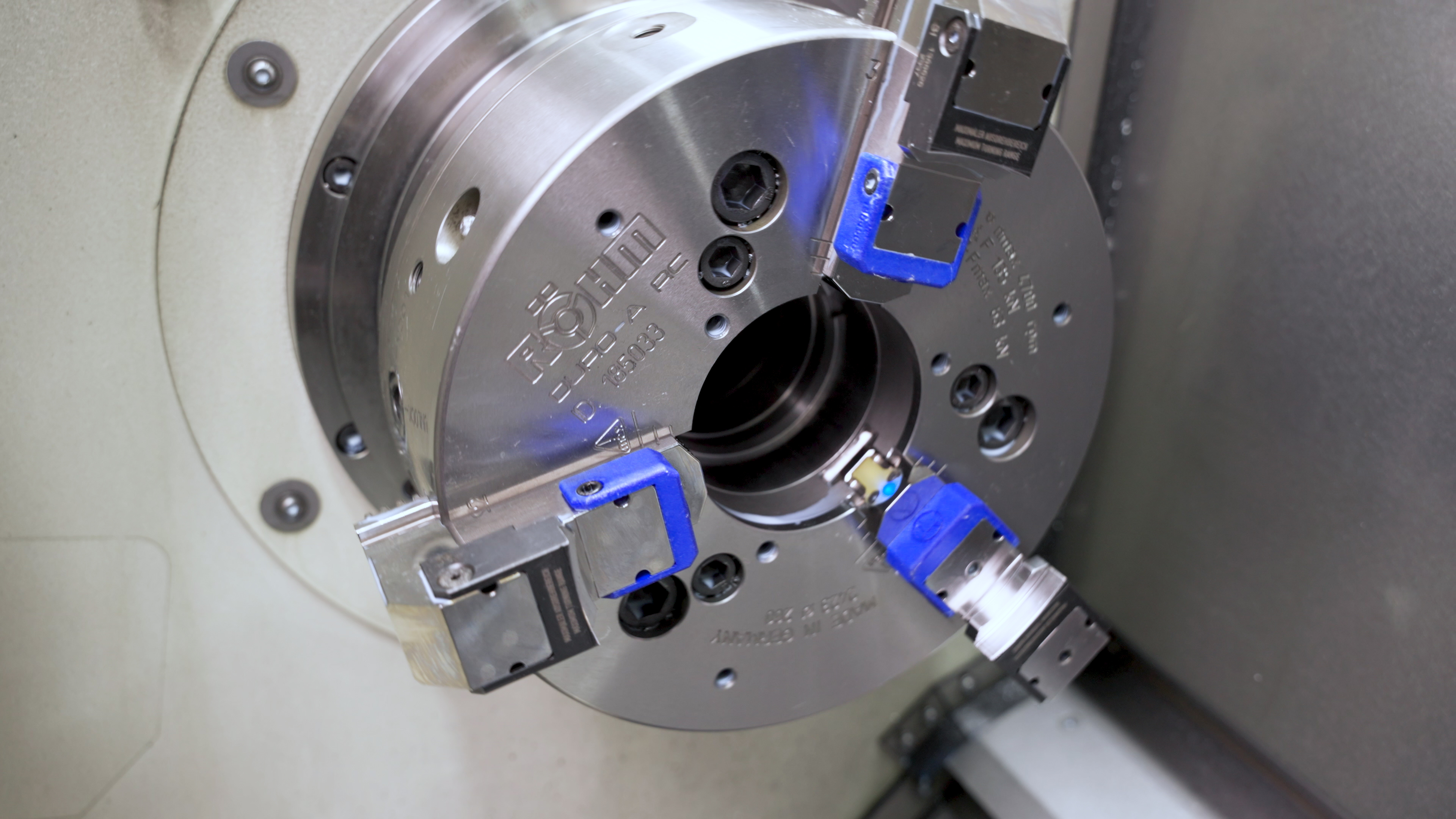

Ready for production on time once again: Röhm specialists overhaul large chuck

Once again, Röhm's service ran like clockwork: The clamping and gripping equipment specialist from Sontheim an der Brenz (Baden-Württemberg) has now impressed with a very unusual maintenance project – the reconditioning of a huge chuck with an external diameter of 5,500 mm. The Röhm specialists spent several weeks at the Sontheim and Dillingen plants and directly at the customer's premises, one of the leading international manufacturers of slewing bearings, to refurbish a Röhm chuck consisting of over 300 individual parts after 17 years of uninterrupted use.Read more

![[Translate to english:] [Translate to english:]](/fileadmin/content/images/presse_pictures/Zentrierspitzen/Zentrierspitze_H_Pro.jpg)

Precise: The new Pro versions of the Röhm live centers

With its new Pro lines HP Pro and HVLP Pro, the clamping and gripping specialist offers its live centers in precision design. With a concentricity of 0.003 mm, the new HP Pro and HVLP Pro live centers from Röhm set standards when it comes to the precise counter-clamping of workpieces on lathes and grinding machines.Read more

Defined clamping force for high-precision components

Higher machine availability, lower part costs, greater safety during machining and comprehensive documentation of measurement data. The new sensorized iJaw clamping jaw from Röhm has all these benefits. The specialist for precision tools, Hellmerich Precision Components (HPC), in Seeboden on Lake Millstatt in Carinthia (Austria), has now confirmed that the iJaw fulfils the promises made by clamping and gripping specialist Röhm in practice.Read more

![[Translate to english:] [Translate to english:]](/fileadmin/user_upload/aktuelles/presse/2024/Roehm_Key_Visual_297_x_2102.jpg)

AMB 2024: Röhm Presents itself as the Specialist for Customized Clamping Solutions

Röhm, the clamping and gripping specialist located in Sontheim an der Brenz (Baden-Württemberg, Germany), generates over 60 percent of its sales with customized clamping solutions that are developed specifically for its customers. The company will be focusing on this expertise at the AMB 2024 show in Stuttgart (Hall 1, Booth 1D31).Read more

![[Translate to english:] [Translate to english:]](/fileadmin/user_upload/aktuelles/2023/Weltpremiere_f%C3%BCr_die_Nachr%C3%BCstl%C3%B6sung_der_smarten_Spannbacke_iJaw_von_R%C3%B6hm/iJaw_2023_B02_ba_grau.png)

World premiere for the retrofit solution of the smart clamping jaw iJaw from Röhm

Röhm is adding a retrofit solution to its iJaw product range. The clamping and gripping specialist from Sontheim an der Brenz (Baden-Württemberg), presents with immediate effect another world first with the "iJaw After Market Solution". The iJaw measuring clamping jaw is equipped with sensor technology and wireless data transmission which measures the clamping force in real time during machining, can now be retrofitted to all existing turning machines.Read more

AMB premiere for the smart chuck jaw “iJaw” from Röhm

From now on, clamping is smart: Röhm, the clamping and gripping specialist based in Sontheim an der Brenz (Baden-Württemberg, Germany), is presenting its world premiere iJaw at AMB in Stuttgart. It is the first chuck jaw ever to be equipped with sensor technology and wireless data transmission. It allows the clamping force to be measured in real-time directly during machining. Data is transmitted to a gateway via the industry standard IO-Link Wireless.Read more

Made to measure in the spindle: HSK-Flex, the first modular tool clamp

Until now, tool clamps for automated spindle-driven Machining Centers have been custom-made, one-off products. Above all, this takes time. But not everything on such an assembly always has to be designed from scratch. The HSK-Flex from Röhm is the first modular tool clamp on the market. It can be used to fit spindles of very different lengths quickly. “Engineered to Order” thus becomes “Configure to Order” production.Read more

F-Senso 2: The new all-rounder from Röhm for clamping force measurement

From now on, only one clamping force measuring device is needed in the workshop, the laboratory, and production: the new F-Senso 2 from Röhm. The clamping and gripping specialist, based in Sontheim an der Brenz (Baden-Württemberg, Germany), is presenting its new modular system at the AMB in Stuttgart and the IMTS in Chicago. It replaces both the previous F-Senso chuck and the spindle clamping force measuring devices.Read more

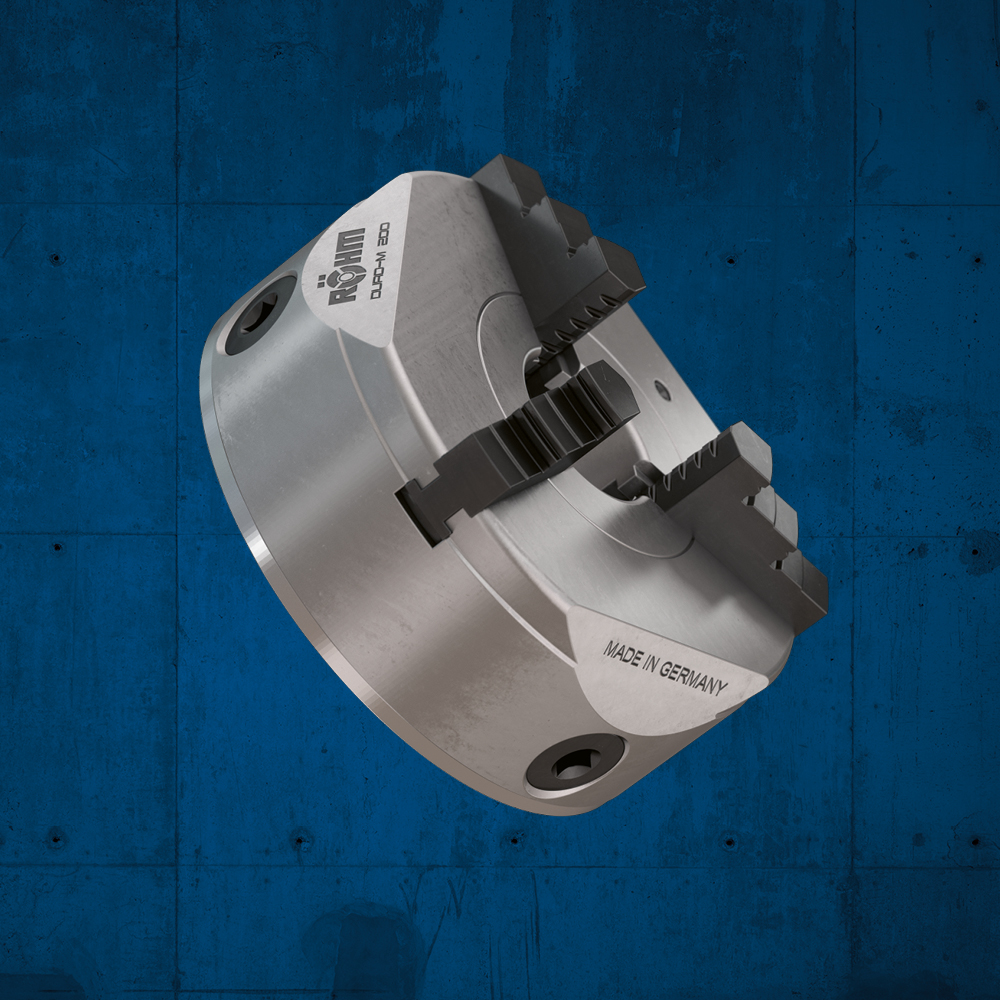

DURO-M from RÖHM: The new lathe chuck generation provides high power transmission

The variable machining of turned parts has never been easier. This is made possible with Duro-M, the new geared scroll chuck, innovative lens geometry and optimized power transmission by Röhm. The specialist for clamping devices and grippers, headquartered in Sontheim an der Brenz (Baden-Württemberg, Germany), provides its innovation by default in all diameters from ø74 m to ø1250 mm, further sizes are available on request. There is no limit with regard to the number of jaws: Röhm supplies its new lathe chuck generation across the whole range with two, three, four or six jaws. This way, even particularly thin-walled workpieces can be clamped and machined perfectly.Read more

Help for refugees: Röhm hands renovate house for families from Ukraine

Full commitment for refugee families from Ukraine: For six weeks, more than 40 employees of Röhm GmbH, headquartered in Sontheim, worked in the evenings and on weekends to spruce up a house in neighboring Bächingen. It was renovated and furnished to the hilt so that a family of five from the Lemberg region and another mother and child can now live in the house for a year free of charge. The rent for the house is paid by the TOOLS FOR LIFE Foundation while the furniture was donated by the company's employees and their families. The Bayern Fan Club Sontheim participated in the project with a donation of EUR 999.Read more