From R&D to automation to control engineering, measurement technology is a vital element of modern manufacturing. Most manufacturers and suppliers realize that they need first-rate clamping to stay competitive in today’s world – especially as the market enters the Industry 4.0 era – and many are actively looking for workholding solutions that can meet the rigorous demands of measurement technology environments.

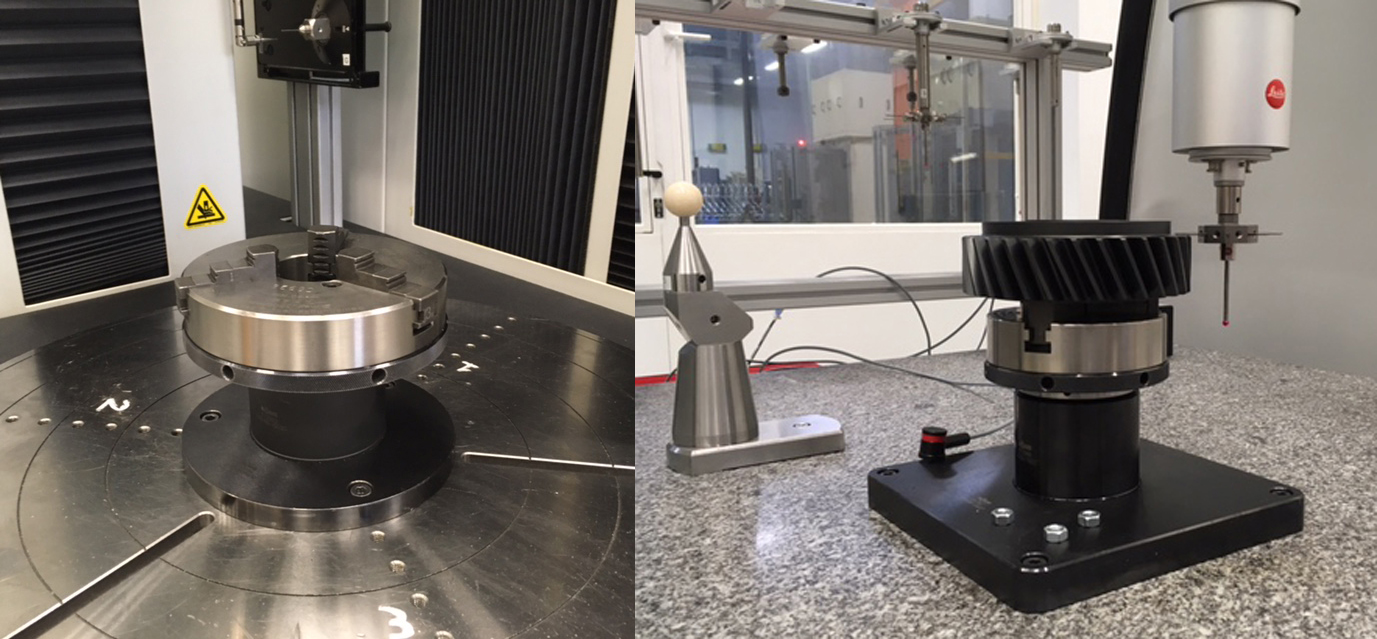

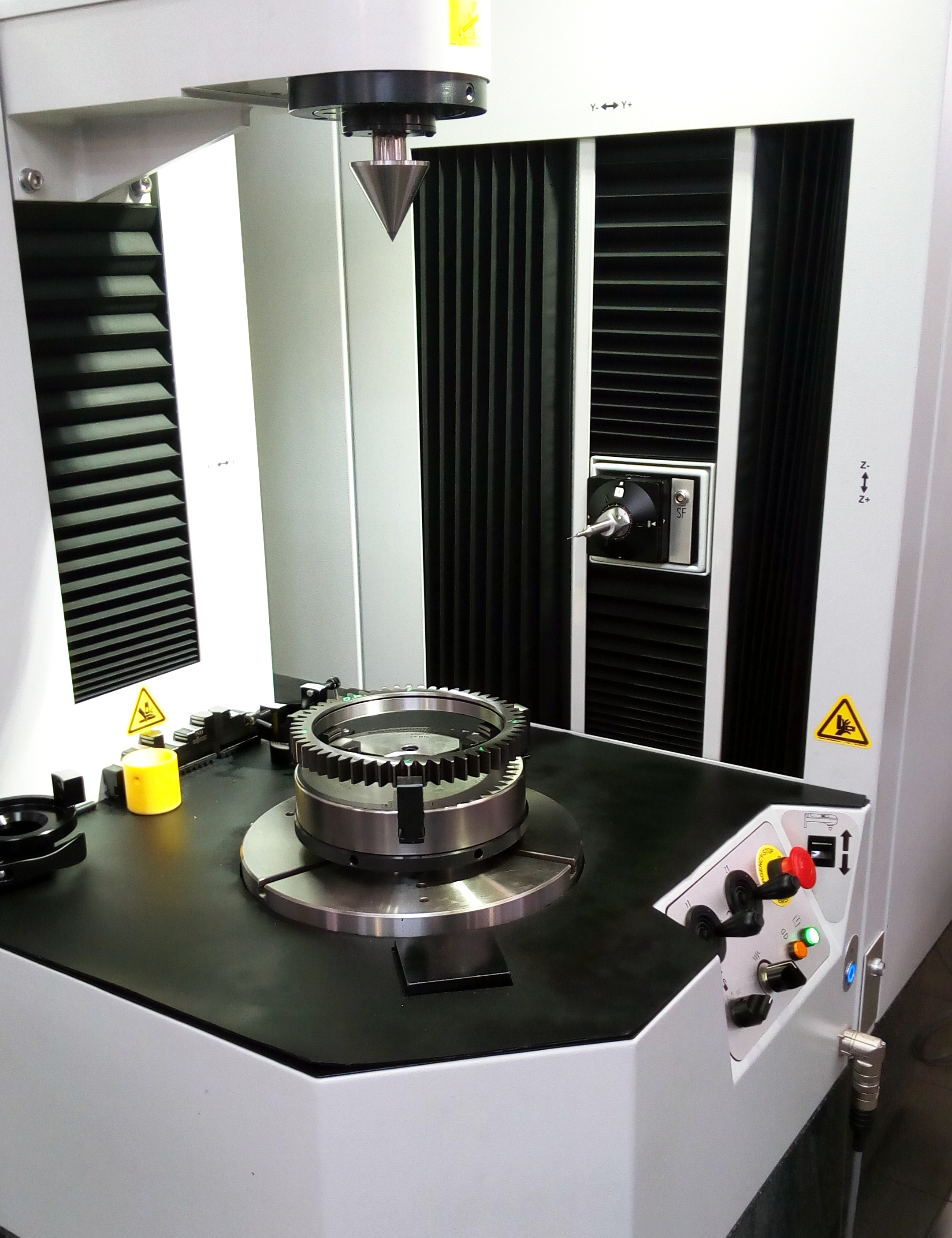

Lever-scroll chucks from RÖHM

Headquartered in Sontheim a.d. Brenz in southern Germany, Röhm has established itself as a global leader workholding for industrial turning, milling, grinding, and drilling. Röhm also offers reliable, sophisticated clamping solutions for measurement technology applications. One of Röhm’s most popular solutions for measurement technology is the KRF lever-scroll chuck. Available in a three- and a four-jaw option, the KRF lever-scroll chuck works seamlessly with contemporary measuring machines. The KRF incorporates an easy-to-use lever-locking ring and offers unsurpassed workpiece positioning and handling. It has a cylindrical center mount and its jaws are ground for precise results regarding concentricity.

Other RÖHM products for measurement technology

Commonly used on jig boring machines, Röhm’s high-precision grinding and control vises are ideal for any job that demands flawless clamping accuracy, including measurement work. Made from alloyed tool steel and precision ground these vises offer easy handling and universal usability. Additionally, Röhm’s drill vises are ideal for clamping workpieces on complex measuring machines. Röhm also offers dead centers for counter-clamping workpieces. Its cartridge mandrels, in particular the MZE, are distinguished by their impressive concentricity, runout accuracy, and repeatability.