Design and Manufacturing of your Clean Room Equipment FROM THE SPECIALIST FOR CLAMPING, GRIPPING AND HANDLING TECHNOLOGY

Many large machine and plant manufacturers worldwide list us as a standard supplier for drill chucks, lathe chucks, centers, robot ripping technology or clamping devices. Together with the companies that it supplies, ROHM has now entered the cleanroom. Take advantage of our know-how for cleanroom-compatible clamping, gripping and handling technology. Röhm develops and produces components and assemblies for your specific production process.

We need your consent to load the YouTube video service. By accessing the YouTube-video, your personal data will be transmitted to the platform operator and third countries. Further information on this can be found in our privacy policy.

Optics

Set-ups for final machining and assembly of precision optical components

Precision mechanics

Clamping and gripping tools for mechanical processing of housings for high quality clocks

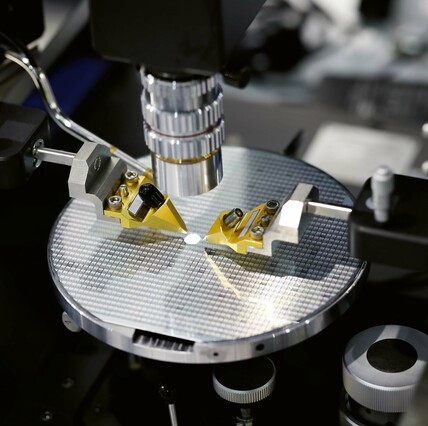

Semiconductors

Mechanical assemblies for system and process solutions including cleaning and assembly in the clean room environment

Medical technology

Clamping tools for final machining of implants

Everything starts with individual product development, which considers the requirements of the cleanroom in addition to the solution of the actual task. It depends on three components: selection of materials, product design and manufacturing process.

RÖHM produces cleanroom-compatible clamping, gripping and handling technology with maximum vertical integration. Final production and packaging also take place in our own cleanroom tent up to cleanroom class EN ISO 7. This even includes the installation of larger assemblies.

Examples handling technology | Examples of components and Assemblies |

|

|

THE CLEANROOM TENT FROM RÖHM

Setting up the Röhm clean room | MCRT Heuchelheim |

Clean room class | ISO 7 |

Maximum manageable component volume | approx. 2 m³ |

Maximum component mass handled | 1.000 kg |

Upstream gray room | With materials and personnel airlocks, with cleaning baths for incoming and outgoing objects |

Other features | ESD protection flooring, dark room with particle measuring technology |

WIDE SELECTION OF MATERIALS

| STEEL | PLASTIC |

|

|

| ALUMINUM | |

|

|

ARE YOU LOOKING FOR AN INDIVIDUAL SOLUTION?

Talk to us. We are here for you.