ASEDO GmbH + Co. KG is an innovative partner for customized, future-proof solutions in the manufacturing and process industries. For almost three decades, the Middle Franconians have repeatedly placed their trust in products from RÖHM GmbH. When those responsible for a new project set out to find the most suitable offer, they once again opted for clamping devices from the supplier based in Sontheim a.d. Brenz.

Dombühl in the district of Ansbach is part of the Nuremberg metropolitan region. A good 20 km south of the tourist magnet Rothenburg ob der Tauber is home to ASEDO, a specialist in metalworking and control cabinet construction. The South German company's diverse range of manufacturing services extends from milling, turning, laser cutting, welding, and edging to design and electrical assembly.

“We have been in the market since 1986 – and have been growing and developing steadily ever since,” reports Andreas Schwab. “Today, we employ over 170 people who work in modern, safe workplaces with well-maintained machinery,” emphasizes the managing director. “Among other things, we manufacture machine parts for the chemical and pharmaceutical industries and therefore have extensive experience with individual parts made of rust- and acid-resistant materials. In addition, we build control cabinets and control systems for production, packaging, and conveyor systems in special machine construction.”

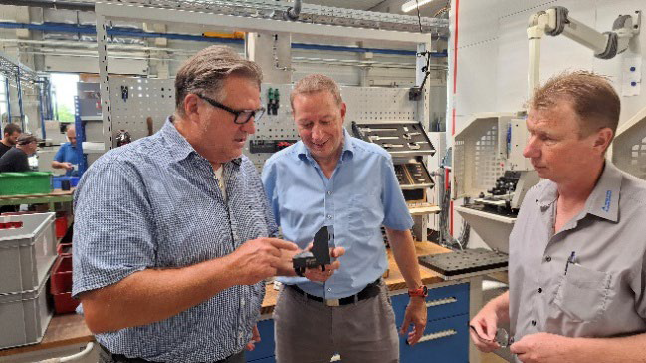

“The collaboration between ASEDO and RÖHM has been going on for a long time, certainly almost 30 years,” estimates Dirk Gaarz, sales engineer at the clamp and gripping specialist. “Since 1997, to be precise,” adds Managing Director Schwab with a slight smile: The cooperation began with his predecessor Friedrich Mayer. Production has always been tailored to RÖHM clamping devices – and the Middle Franconians have always been very satisfied with them.

Everything from a single source

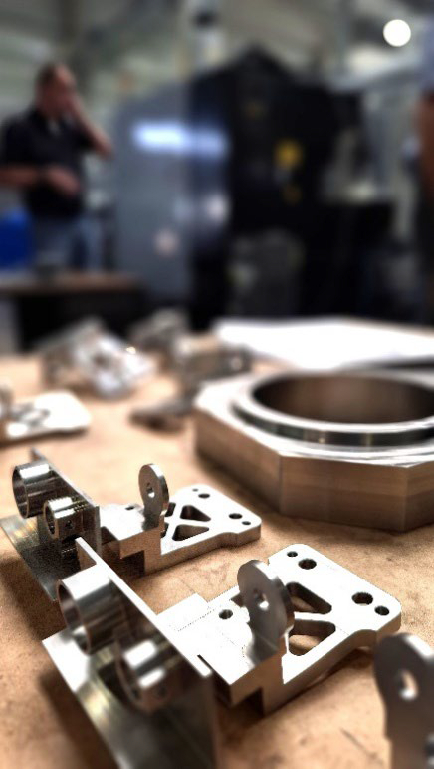

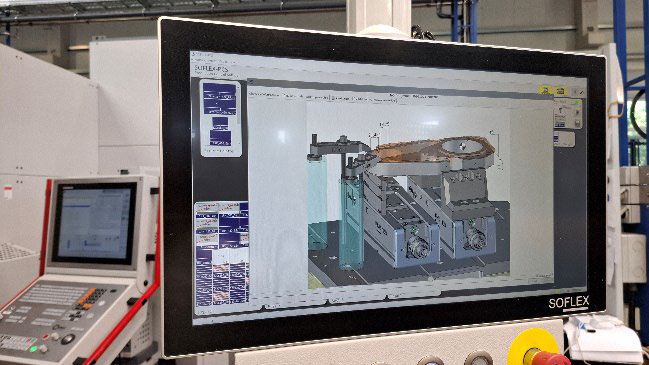

For the new project, compact clamps for the pallets were sought for the new plant, which now has three Hermle C42 machining centers – including the Hermle RS2L automation solution. In 2021, the Gosheim-based supplier delivered its first machine, followed by the automation system. ASEDO then placed the second and third machining centers directly at the robot cell as well. The ASEDO team designed and manufactured the first prototypes of the RÖHM clamping jaws themselves – but attached great importance to RÖHM assuming product liability for these clamping devices. “The fact that RÖHM agreed to this was the decisive factor in our positive decision on this project,” recalls Schwab.

Decades of cooperation

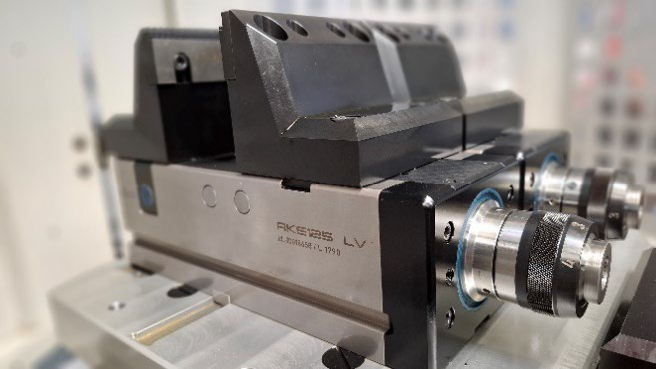

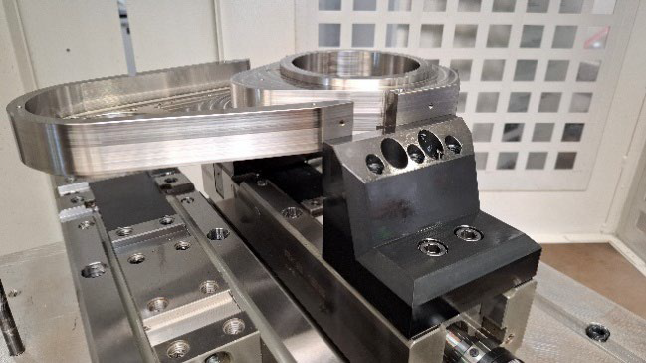

“The standard RKE basic was too heavy and too long, so my predecessor Gerhard Häutle suggested the lighter RKE LV with the same clamping force but a shorter design,” explains Dirk Gaarz. As Gerhard Häutle is retiring, he is handing over the project to his colleague Gaarz, but will always be available for further consultation: "ASEDO had already designed special jaws for production, which were adapted to the RÖHM clamps and offered as complete clamping devices. In this context, it was also particularly important to those responsible at ASEDO that RÖHM assume liability for these special jaws. After initial trials, the choice fell on the RKE125 LV clamps with low weight (27 kg), enormous clamping force, and a suitable jaw width of 125 mm. These now carry the jaws specially designed by ASEDO."

Andreas Schwab adds: “We were looking for a suitable clamping device for the automation of single-piece production with pallet storage for individual part processing. RÖHM was certainly our favorite due to its many years of excellent experience – and ultimately won the contract – although we did look at alternatives in terms of quality and service support. The implementation went extremely well throughout the entire project. We also plan to expand and increase the magazine capacity of the workpiece storage system in the near future.”

Process initiation and production description

After the first supplier was eliminated during the current search, ASEDO focused on the clamping devices from RÖHM that were already in production. However, these were only suitable for five-axis machining to a limited extent. "Our production inventory included selfmilled jaws. Due to the modifications, this was already an optimal solution and suitable for five-axis machining. Nevertheless, we wanted to move even closer to a ‘standard’ solution. After consultation and joint coordination, RÖHM was able to offer us these jaws as designed and tested original parts from RÖHM. This is a top-notch service that we are receiving here," Schwab appreciates.

And the Sontheim-based company provided further helpful support: There were trials with the clamping devices and on-site consultation in cooperation with ASEDO. Customer requirements were taken into account in collaboration with the RÖHM design department. The Sontheim test clamps were initially delivered to Andreas Mack (production foreman) and industrial foreman Wladimir Lang. “The process encompassed design, production, and testing, right through to the products we had devised that are now available to order,” summarizes Schwab.

Advantages for the user

The new RÖHM products were first used on Hermle's single machine and then transferred to the RS2L robotics and automation solution, also from Hermle in Gosheim. Subsequently, two additional Hermle machines were integrated into the process, which produces even complex parts reliably and with high productivity. RÖHM products are now installed as standard clamping systems for the rest of the milling production in order to maintain a uniform clamping concept. "In the future, we will only use two different clamping devices. The automated system now covers almost 35 percent of total production in our CNC milling division in its final configuration,“ Schwab explains. ”The modification of the jaws was a direct solution developed by employees based on previous requirements. The idea was to use a vice originally intended for use in the 3-axis range for 5-axis applications. We succeeded in implementing this as a standard product at RÖHM.“

Summary and outlook

Andreas Schwab, Managing Director at ASEDO, personally accompanied the project, but emphasizes appreciatively: ”The CAM programmers and IT department, as well as the production team, were fully involved from the very beginning. That is the real key! In this respect, we can all be proud of having implemented this challenging concept so effectively – and RÖHM and its team played a very significant role in this." Industrial foreman Wladimier Lang adds: “The combination of top people from the companies, excellent programs from the CAM experts, and mutual exchange within the team – that was the key to this success.”

“We were able to implement the project from scratch. We started with state-of-the-art facilities and top-of-the-line equipment in order to achieve highly effective machining right from the start,” explains Schwab. “Usually, such a process runs the other way around. We practically tackled the whole thing backwards... and that is only possible with the full commitment of the team.” “Without the reliability and precision of the RÖHM clamping jaws, the success of the project might have been jeopardized,” adds Gerhard Häutle. “However, not a single service call has been necessary in the last three years. That's great and shows that the equipment works excellently.”

“RÖHM's delivery and support have also always been first-class,” confirms Wladimir Lang. The system now covers around one-third of the entire CNC milling production. Managing Director Andreas Schwab concludes: “Ultimately, everything worked out as we had imagined. The logical conclusion is that we already have 45 RÖHM clamping devices in our further planning.”

About Röhm GmbH:

Röhm GmbH, with its headquarters in Sontheim an der Brenz (Baden-Württemberg) and production sites in Dillingen (Bavaria) and St. Georgen (Black Forest), specializes in the development, design, and manufacture of high-precision, robust and durable clamping and gripping devices. The products are "Made in Germany" Röhm's clamping and gripping devices are used worldwide by almost all renowned manufacturers in the automotive industry, railroad technology, watches, medical technology, power engineering as well as in woodworking. Röhm also manufactures special clamping devices and handling equipment for use in cleanrooms in accordance with cleanroom class ISO 7.

Röhm has its own subsidiaries in England, France, Italy, Switzerland, Spain, Poland, USA, China, and Mexico. Founded in 1909, the company quickly became known worldwide for its drill chucks. To this day, Röhm develops and manufactures drill chucks at the Sontheim location that are used worldwide by almost all manufacturers on stationary as well as hand-operated electric tools for screwing and drilling.

www.roehm.biz