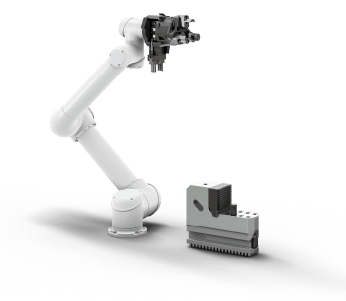

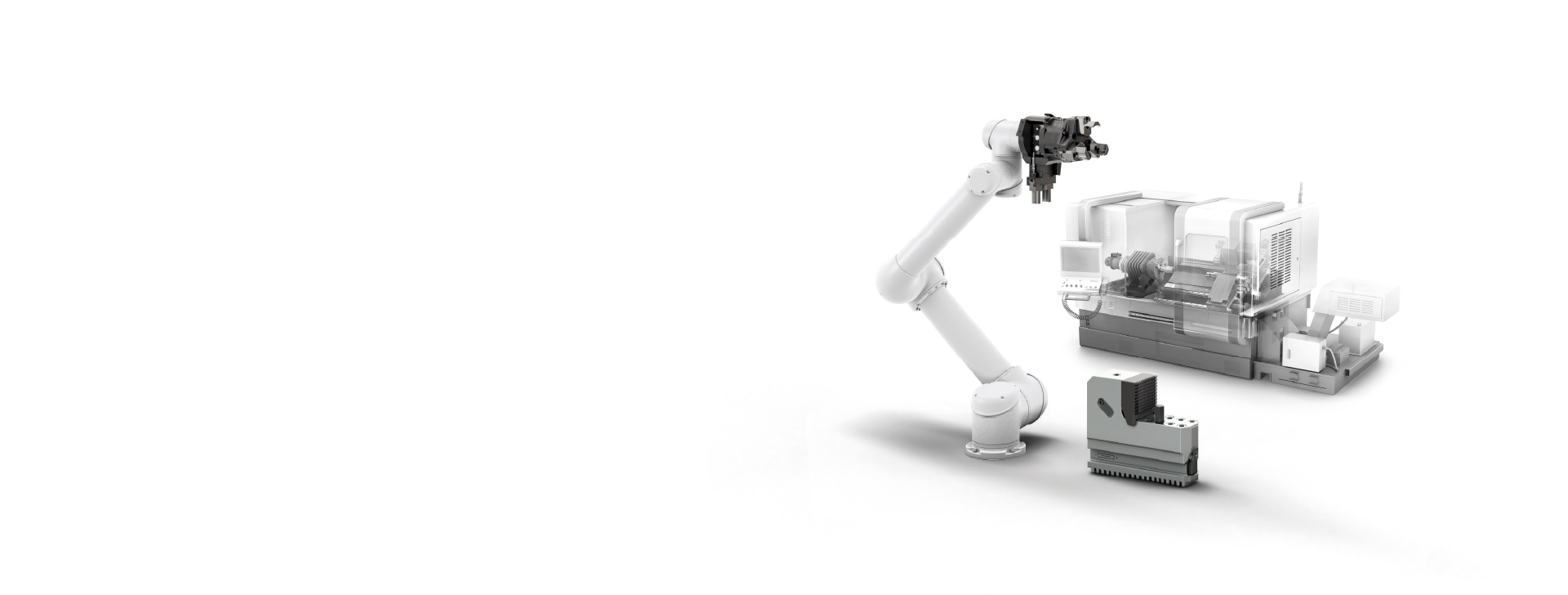

iJaw

Automation solution

Our solution combines the automatic loading and unloading of workpieces with integrated quality control.

Enhanced machining quality and precision

through concentric clamping with the required clamping forceLower workpiece rejection rates

by preventing severe imbalance and continuously monitoring clamping forcesHigher productivity and cost efficiency

thanks to integrated measurement capabilitiesSeamless, flexible, and cost-effective integration

into existing production environments

Your contact:

Johannes Diepold

Product Manager iJaw

Tel: +49 7325 / 16-359

E-Mail: smarter.clamping@roehm.biz