Press

![[Translate to english:] [Translate to english:]](/fileadmin/user_upload/aktuelles/2023/Weltpremiere_f%C3%BCr_die_Nachr%C3%BCstl%C3%B6sung_der_smarten_Spannbacke_iJaw_von_R%C3%B6hm/iJaw_2023_B02_ba_grau.png)

World premiere for the retrofit solution of the smart clamping jaw iJaw from Röhm

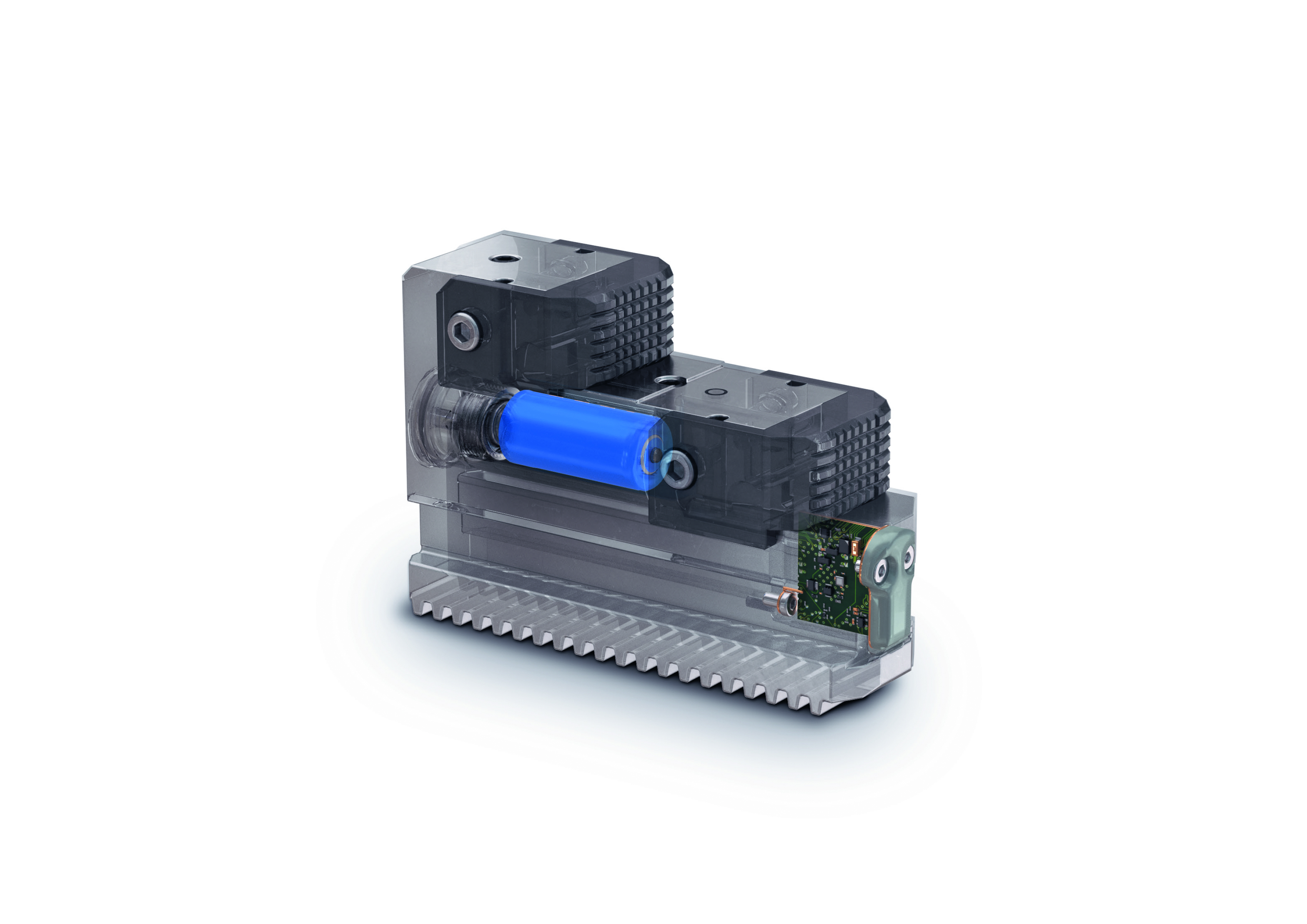

Röhm is adding a retrofit solution to its iJaw product range. The clamping and gripping specialist from Sontheim an der Brenz (Baden-Württemberg), presents with immediate effect another world first with the "iJaw After Market Solution". The iJaw measuring clamping jaw is equipped with sensor technology and wireless data transmission which measures the clamping force in real time during machining, can now be retrofitted to all existing turning machines.Read more

AMB premiere for the smart chuck jaw “iJaw” from Röhm

From now on, clamping is smart: Röhm, the clamping and gripping specialist based in Sontheim an der Brenz (Baden-Württemberg, Germany), is presenting its world premiere iJaw at AMB in Stuttgart. It is the first chuck jaw ever to be equipped with sensor technology and wireless data transmission. It allows the clamping force to be measured in real-time directly during machining. Data is transmitted to a gateway via the industry standard IO-Link Wireless.Read more

Made to measure in the spindle: HSK-Flex, the first modular tool clamp

Until now, tool clamps for automated spindle-driven Machining Centers have been custom-made, one-off products. Above all, this takes time. But not everything on such an assembly always has to be designed from scratch. The HSK-Flex from Röhm is the first modular tool clamp on the market. It can be used to fit spindles of very different lengths quickly. “Engineered to Order” thus becomes “Configure to Order” production.Read more

F-Senso 2: The new all-rounder from Röhm for clamping force measurement

From now on, only one clamping force measuring device is needed in the workshop, the laboratory, and production: the new F-Senso 2 from Röhm. The clamping and gripping specialist, based in Sontheim an der Brenz (Baden-Württemberg, Germany), is presenting its new modular system at the AMB in Stuttgart and the IMTS in Chicago. It replaces both the previous F-Senso chuck and the spindle clamping force measuring devices.Read more

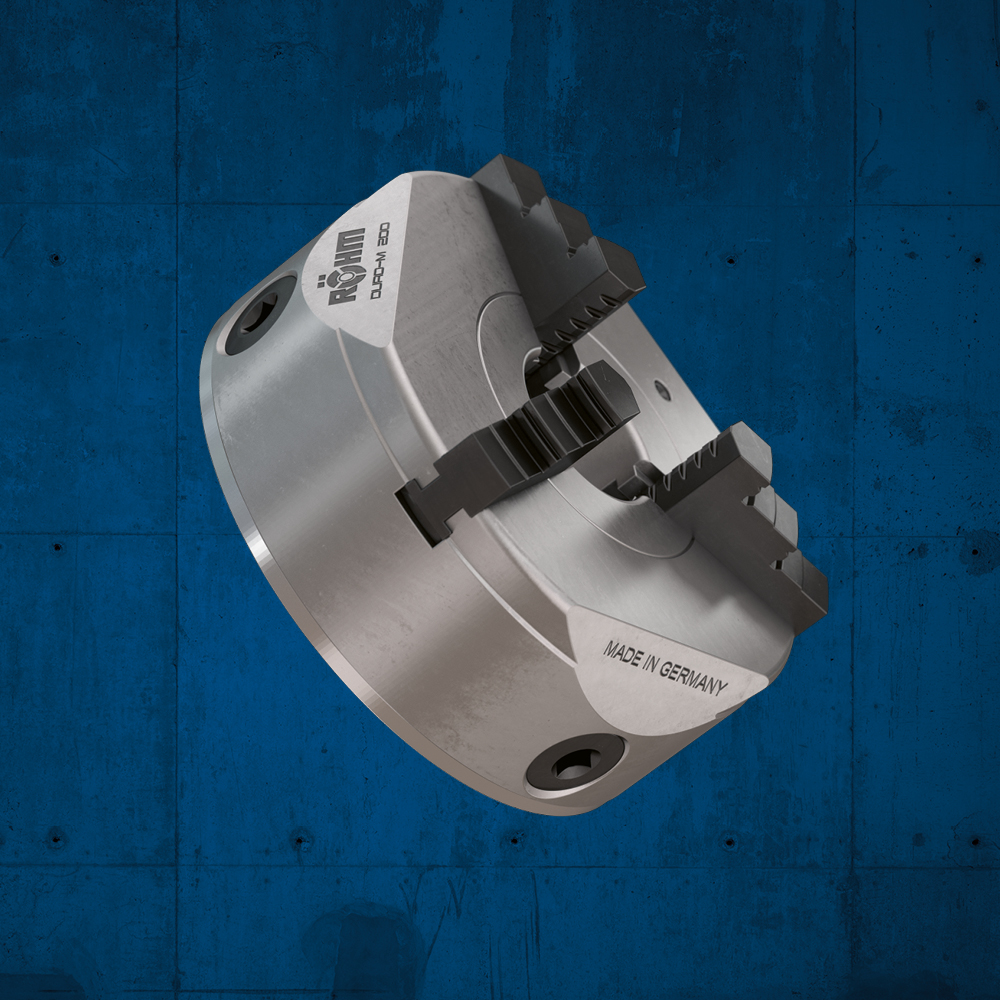

DURO-M from RÖHM: The new lathe chuck generation provides high power transmission

The variable machining of turned parts has never been easier. This is made possible with Duro-M, the new geared scroll chuck, innovative lens geometry and optimized power transmission by Röhm. The specialist for clamping devices and grippers, headquartered in Sontheim an der Brenz (Baden-Württemberg, Germany), provides its innovation by default in all diameters from ø74 m to ø1250 mm, further sizes are available on request. There is no limit with regard to the number of jaws: Röhm supplies its new lathe chuck generation across the whole range with two, three, four or six jaws. This way, even particularly thin-walled workpieces can be clamped and machined perfectly.Read more

Help for refugees: Röhm hands renovate house for families from Ukraine

Full commitment for refugee families from Ukraine: For six weeks, more than 40 employees of Röhm GmbH, headquartered in Sontheim, worked in the evenings and on weekends to spruce up a house in neighboring Bächingen. It was renovated and furnished to the hilt so that a family of five from the Lemberg region and another mother and child can now live in the house for a year free of charge. The rent for the house is paid by the TOOLS FOR LIFE Foundation while the furniture was donated by the company's employees and their families. The Bayern Fan Club Sontheim participated in the project with a donation of EUR 999.Read more

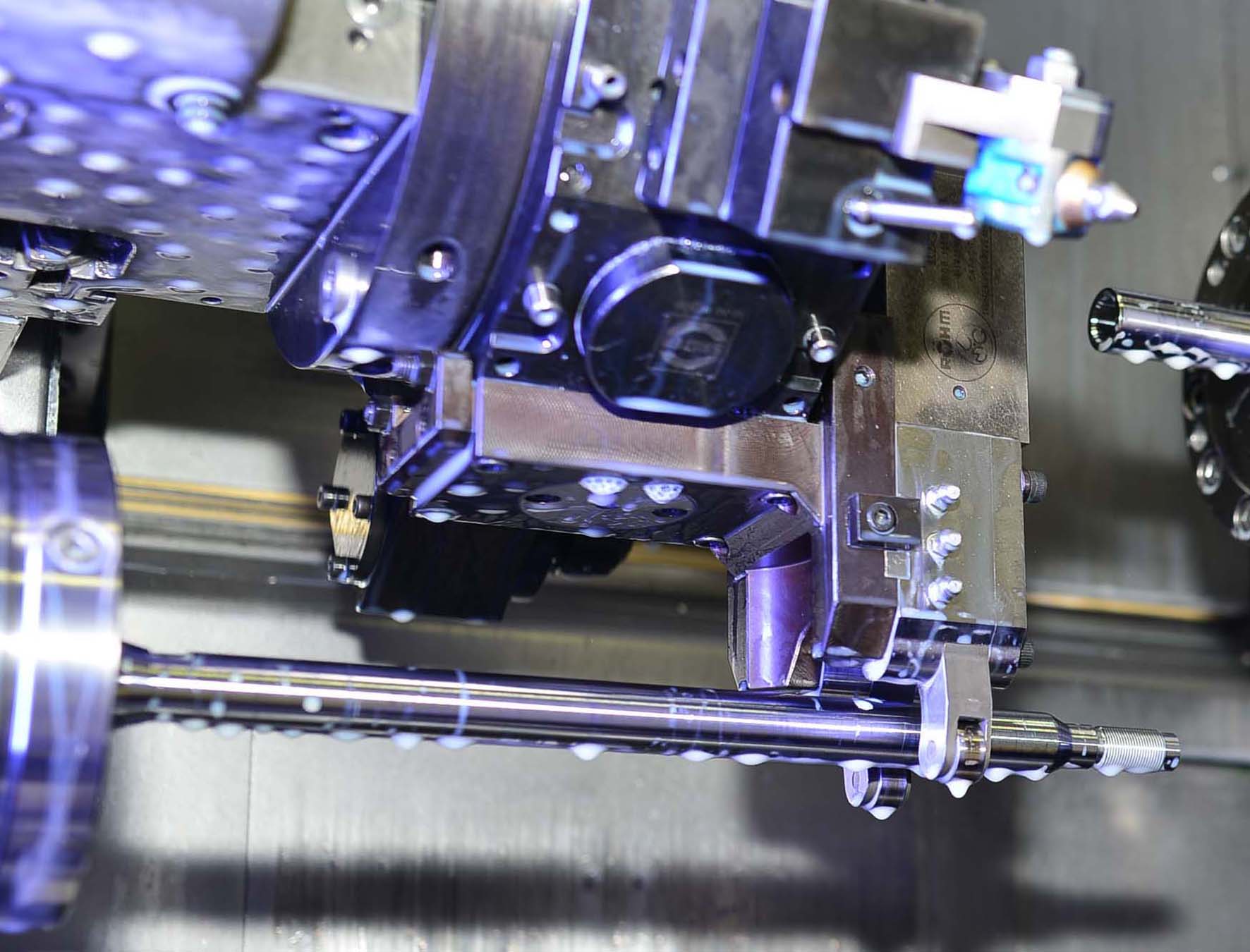

Turret mounted, coolant operated steady rest

Even when no steady rest is provided in an existing lathe turret – it is not necessary to retrofit an oil hydraulics unit to control a turret mounted steady rest. There is an innovative solution that uses the coolant pressure at the control to signal the steady rest to clamp as per the program and it is opened via the spring pressure. This product has been a joint collaboration between Röhm and WESA GmbH.Read more

Röhm's IoT solution for real-time measurement of clamping force during machining does not even have a cable

In Milan on September 30, 2021, the clamping technology specialist Röhm is presenting the iJaw clamping jaw for the first time at EMO 2021 in Milan. It allows the clamping force to be measured in real time during machining. Röhm thus solves a problem for which there has been no accepted industrial solution up to now: the clamping force is usually set by the operator of the machine tool and is a matter of experience. Errors during machining due to incorrect clamping force or workpiece loss are therefore preprogrammed. The iJaw presented by Röhm integrates sensor technology for clamping force measurement as well as wireless data transmission in a full-fledged clamping jaw. The measurement takes place directly at the clamping point to the workpiece; the data transmission to a gateway makes use of the upcoming industry standard IO-Link Wireless. The gateway can be connected to the machine control system via the integrated Profinet interface and/or sends the data to a cloud via the integrated LAN interface.Read more

Reliable control of vibrations and dimensional accuracy

Mannstaedt is a global market leader in the manufacture of hot-rolled special profiles. When it started looking for a high-quality clamping device for heavy-duty cutting, it turned to the German gripping and clamping technology specialist, Röhm.Read more

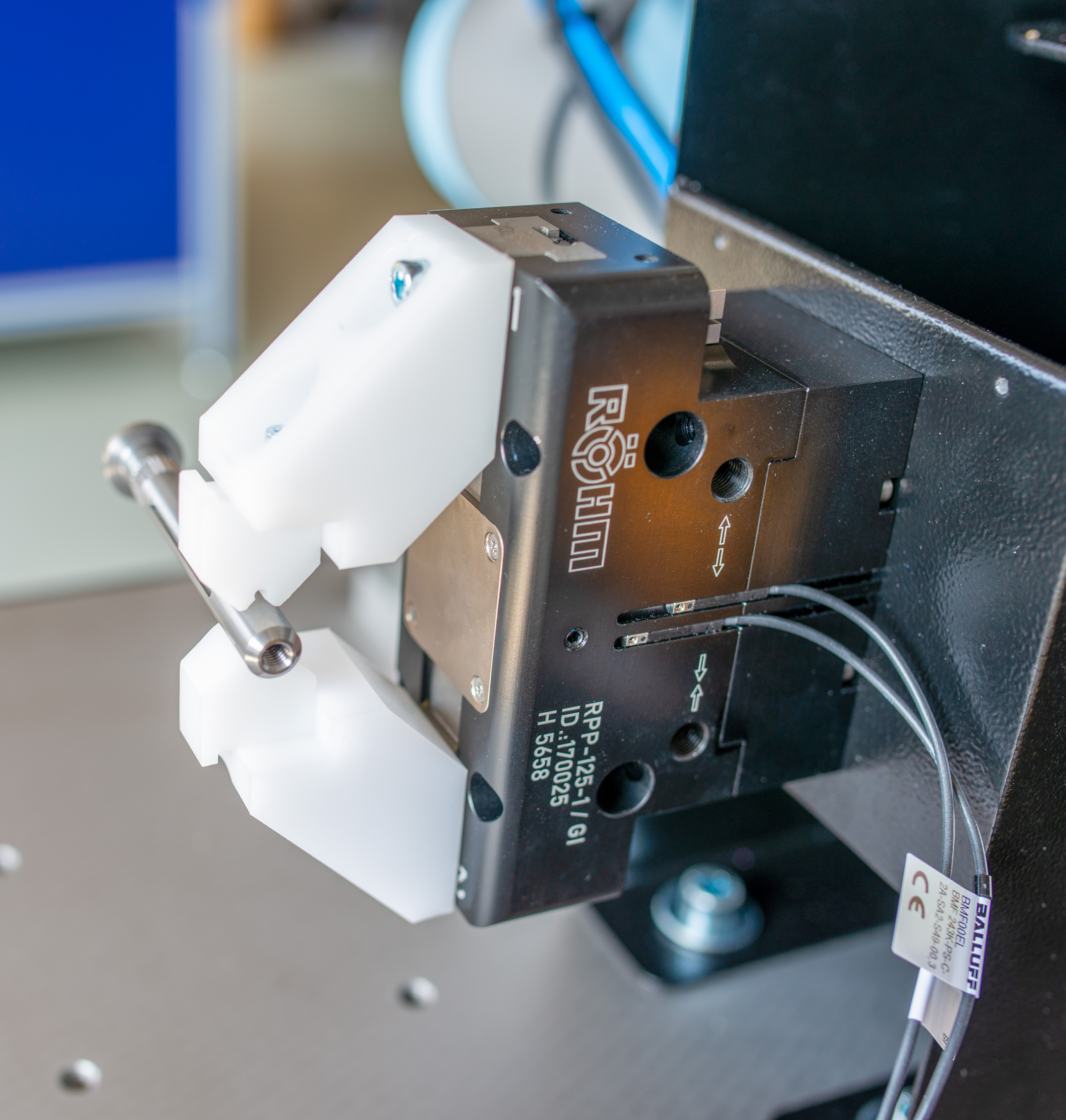

Two-jaw gripper - High clamping force, low weight

You can only use what you know. At BoKa Automation this would be grippers from Röhm. Based on many years of positive experience with products from the clamping device specialist, BoKa relies on two-jaw grippers for its newest development. With these, a robot grips individual workpieces for further part handling directly on the machine.Read more