Production of cast and stainless steel housings with a Röhm key bar chuck Duro-TA XT

NTG has been a sought-after partner for manufacturing cast and VA housings since 1968. The robust and long-lasting quality products are used in small numbers in mechanical and plant engineering. The company uses a DMG DMC 210 FD for turning and milling work. To make machining even faster and more flexible, NTG relies on the new manual chuck DURO-TA XT from Röhm. That way, it is possible to change from large to small workpieces in just minutes.

"Speed is our greatest competitive edge in manufacturing cast and VA housings," emphasizes Bernd Rützel. The Production Technology department manager of NTG Neue Technologien GmbH u. Co. KG from Gelnhausen in South Hesse tells about projects enthusiastically like the current one in which they had to manufacture cast steel housings with complex exterior shapes for a plant manufacturer. "Conditional on new technologies and increased requirements placed on the complexity of the machining technology that goes along with them, the machinery was configured at a high technological level. Parallel to this, parts manufacturing was established as another line of business in order to ensure the utilization of our complete processing machines," continues Bernd Rützel.

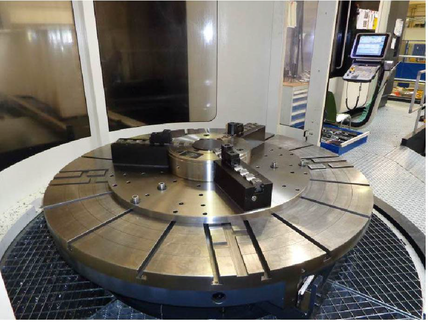

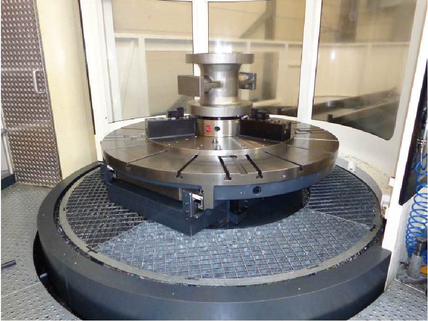

With great reliability, cast and VA housings are produced on request mainly in singlepiece production from the idea to the development to the completion. NTG recently invested in an ultramodern turning/milling center from DMG to manufacture them. To make sure that the DMC 210 FD can utilize its capacity as flexibly as possible, NTG chose a DURO-TA XT manual chuck from Röhm. The latest chucks from Röhm with an impressive 1200 mm diameter are characterized by their compact design, workpiece accessibility and flexibility despite their size.

The DMG was equipped in the factory with a jaw box from Röhm for a clamping diameter of up to 1200 mm. And, the company had had good experience with products from Röhm aside from the DMC 210 FD. It was obvious to Bernd Rützel to also ask the Sontheim team about a centric clamping 3-jaw chuck to be used for machining the housing.

"An important selection criterion was the high inherent stiffness of the lathe chuck. Röhm was able to prevail over the other providers here. This was achieved by having the entire unit sitting on a thicker aluminum base plate," says Jochim Nagel, Technical Sales Advisor from Röhm.

"Vibrations like the ones that can occur with such lathe chucks and which carry over to the workpiece and hence the tools, must not arise, because they damage the tools," summarizes Bernd Rützel.

When choosing tools, NTG makes use of standard tools if at all possible in order to manufacture cost-effectively. Hence, the workpieces are machined with hard metal tools. Vibrations would have a negative effect on the tools. The situation is similar for full milling cutters. "Just one chipped cutting edge, and the entire milling cutter can no longer be used," says Bernd Rützel.

Chuck highly adjustable: from 300 to 1200 millimeters

Through the extended and easily detached guideways of the manual DURO-TA XT chuck, Röhm has managed to more than double the clamping range and simultaneously make it flexible to use. The chuck is very well suited to machining with frequent changes from large to small workpieces, because in such a case, only the guideways have to be detached. That way it considerably reduces the set-up times and hence the costs. "That is a tremendous advantage when manufacturing small numbers," continues Bernd Rützel.

Thanks to the weight reduction of up to 75 percent over conventional chucks, the DURO-TA XT utilizes the maximum potential of the machine tools. As a result, it is possible to clamp higher workpiece weights with a lower load on the machine table. Its minimal interfering contours make the chuck even more attractive and flexible to use.

Through the high radial run-out accuracy, you can retool quickly from the first to the second set-up. Time-consuming alignment and readjustments are not always necessary. Furthermore, the process can also be interrupted and you can retool for other manufactured parts without having to put up with increased set-up times. Through our own top jaws or other tool-based custom jaws from Röhm, bulky valve bodies or other workpieces can also be manufactured easily on the machine. The parts are clamped with a torque wrench in order to achieve a reproducible clamping force.

Bernd Rützel: "High clamping force and radial run-out accuracy, low deadweight – and all of this with a diameter of ca. 1200 mm. Röhm was able to completely satisfy all the requirements that we had." The unanimous opinion of the decision-makers at NTG is that any possible future purchases will be for a DURO-TA XT from Röhm.

Contact

Do you have a special clamping task? Ask us!

Contact your

personal contact person

or write to us at

sales@roehm.biz