Revolver steady rest easily retrofitted

coolant pressure gives the control command

Even if the existing tool turret of a turning center does not have a steady rest, there is no need to retrofit oil hydraulics in order to control a turret steady rest. Here's how it works: the coolant pressure acts as a control signal to close the steady rest according to the program, and spring pressure opens it. This is a joint development by the clamping device manufacturer Röhm and the supplier WESA GmbH.

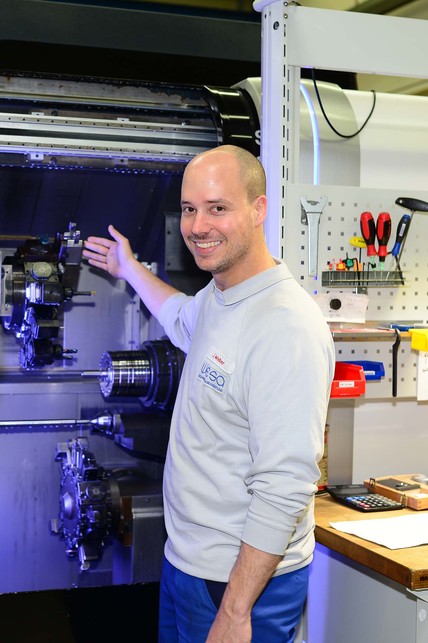

Those who choose WESA, the strong partner for all CNC manufacturing levels in Waldstetten, Swabia, can rely on high quality, fast implementation, and absolute adherence to deadlines. Johannes Weber is proud of these qualities: “We are not the cheap option,” emphasizes the production manager, listing the company's strengths: “We can quickly mass-produce difficult and complex components.” For him, one thing is certain: “When things have to be done quickly, customers come to us and don't go to the big players in the industry, who are geared towards large series and are therefore slow.”

From prototype to series production – fast, flexible, highly accurate

Wesa GmbH in Waldstetten is a family-run company. As a pure service provider, the company focuses on metal processing and employs around 50 people. Specializing in complete CNC machining, the company utilizes an extensive range of machinery – from prototype construction to series production. Whether turning or milling parts, ready-to-install workpieces and systems including hardening and surface finishing, the appropriate machines and tools are available for a wide variety of manufacturing steps. Typical orders include the production of ready-to-install pinions and gear shafts. Its customers include major automobile manufacturers such as Porsche and Daimler, as well as automotive suppliers Bosch and ZF, among others. At Wesa, work is not only highly automated, but also fast and flexible. That is why there are buffer stations between the individual machining centers for turning and milling. “If a turning cell experiences an outage, the entire production does not come to a standstill,” says Johannes Weber, proudly referring to a recent project for a Stuttgart-based car manufacturer: “We manufactured and delivered a completely new workpiece, which required several work steps, in just 13 weeks from the first drawing.”

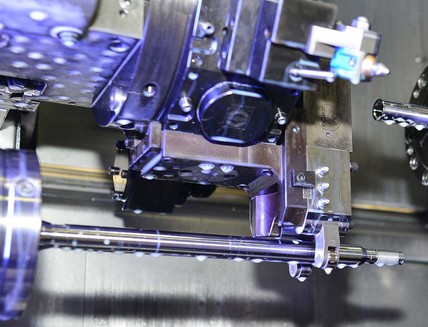

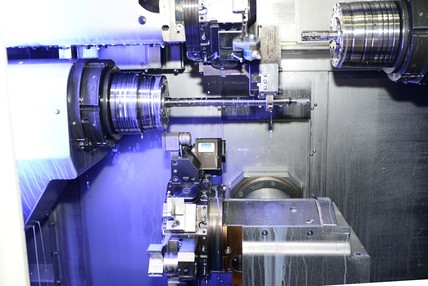

The DMG Sprint 50 CNC turning machine has long been part of Wesa's machine portfolio, enabling the supplier to process raw materials flexibly – simultaneously and unmanned. Long, thin components are mainly manufactured on this machine in Waldstetten. They are workpieces that are usually supported with a steady rest to be able to machine them with high precision.

Small turret and no oil hydraulics

Originally, no steady rest was planned for the Sprint 50 turning center, notes Johannes Weber, but now, thanks to the collaboration with Röhm, there is a fully functional workpiece support – despite the design specifications of the machine: small tool turret, limited working space and no hydraulic connection. The framework conditions from Wesa to Röhm were clearly defined. The manager at the time: "Those are the specifications! The steady rest has to be on there! Just do it!” And 18 to 36 mm had to be adhered to as the clamping range.

It is common for a standard tool turret to have two oil hydraulic connections. But, because Johannes Wesa did not want to install another medium in the machine, the idea matured to use the coolant and the existing line for this purpose to trigger the control commands: Initial market research and implementations did not yield acceptable results. Contact with the clamping device manufacturer Röhm, with whom we have a long-standing partnership, then led to the hoped-for solution to the problem.

Röhm, an internationally active specialist in clamping and gripping technology, has its headquarters in Sontheim an der Brenz and employs around 1,300 people worldwide in over 60 branches and representative offices. Röhm manufactures high-quality clamping technology – from the smallest drill chuck to high-tech power clamping devices. The company's focus is always on topics such as Industry 4.0, lightweight construction, energy efficiency, and additive manufacturing.

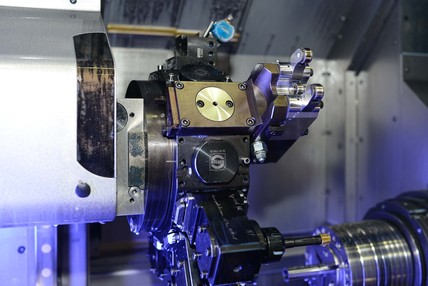

Small, lightweight, and functional steady rest

Although the clamping professionals from Sontheim offer a wide range of steady rests in their standard product line, Wesa required a special solution. “They needed a small, lightweight, functional steady rest,” recalls Röhm sales engineer Richard Sedlak. This was because retrofitting the turning machine with a steady rest was necessary due to the special nature of a new workpiece. Not only did the ratio of the workpiece's diameter to its length – a part of the rear-wheel steering system for a sports car from a premium manufacturer in Swabia – pose a challenge for production, but various concentricity requirements also made things more difficult. “You can't just manufacture a part like this in any workshop,” says Johannes Weber, explaining the situation.

Control commands piggybacked by coolant pressure

The thing that makes this project special is that the steady rest is opened by coolant pressure and closed again by spring force. Richard Sedlak: “There was no hydraulic connection on the machine. And the turret also dictated the installation interfaces: a standardized VDI shaft for holding the steady rest and a connection hole for the coolant. The solution on the machine: The CNC controller moves the open steady rest to position, followed by the signal "coolant on". The clamping arms of the steady rest close and the workpiece is now securely supported and ready for the next machining step. The return spring force then opens the clamping arms of the steady rest again.

Relief valve as a solution

What sounds so simple often turns out differently in practice. Existing coolant lines have a check valve that prevents the coolant from flowing back. This was also the case with the Sprint 50. The consequence is that the pressure remained on the coolant return line, and the spring had to counteract the coolant pressure, which in turn prevented the coolant from draining, resulting in malfunctions in the drainage process. A pragmatic solution was needed, namely a bypass. CNC service provider Wesa and clamping device manufacturer Röhm jointly developed a suitable relief valve. The benefit of this solution: The coolant could now flow out unhindered.

The steady rest operates entirely without oil hydraulics

The project can be summarized quickly. In July 2015, Richard Sedlak, Sales Engineer at Röhm GmbH responsible for Baden-Württemberg, determined the requirements and tasks at Wesa. In January 2016, Wesa ordered two turret steady rests, the first of which was delivered in April 2016. In June, the system was converted to include an additional relief valve with a drain hole. Two weeks later, Röhm delivered the steady rest. In July 2016, Wesa announced: The steady rest works! It took just under a year from the initial contact to the approval of the product. The conclusion about the joint project is unanimous. Richard Sedlak and Johannes Weber confirm: “We work very well together.”

Contact

Do you have a special clamping task? Ask us!

Contact your

personal contact person

or write to us at

sales@roehm.biz