Automated processing of cross joints on round transfer machines

CLAMPING SYSTEMS — FFG Werke GmbH has succeeded in securing an order from China's largest automotive supplier at its production site in Offenburg. Röhm products were used for the clamping devices required for the rotary transfer machine that was ordered.

When a machine tool manufacturer ceases production, the company rarely has a chance of survival. But Witzig & Frank GmbH has achieved the almost impossible. After MAG took over the Offenburg-based manufacturer of machine tools for largescale production in 2009, machine production was discontinued, and the then 144- year-old company had to survive for five years solely through sales and service. Things started looking up again for the machine tool manufacturer in 2014, when the FFG Europe Group took over the company and FFG Werke GmbH was founded. It brings together the various brands VDF Boehringer, Hessapp, Hüller Hille, Honsberg, Modul, the MAG Group, and Witzig & Frank under one roof. Shortly thereafter, FFG made the decision to revive production at the Offenburg site and resume the development and manufacture of Witzig & Frank machines. It quickly became clear that this decision was absolutely the right one: In the first year after the relaunch, the company generated orders of €24 million with new machines and €6 million from service.

The first business relationship with clamping device manufacturer Röhm was established back in 1977, long before the takeover by MAG. When it came to the production of complex parts, Witzig & Frank always relied on the quality and reliability of Röhm solutions and installed them in its systems. It was therefore only natural for the company to continue to rely on Röhm products in its machines after resuming production at its Offenburg site.

Over the past 150 years, Witzig & Frank has developed into a successful designer and manufacturer of highly productive systems for the production of small to mediumsized components in very high quantities. These machines are primarily delivered to customers in the automotive and general mechanical engineering industries, as well as the sanitary and fittings industry. Pascal Schnebelt, Sales Director at Witzig & Frank, explains why these industries in particular benefit greatly from the systems from Offenburg: "Our customers produce very high volumes and want as little logistics as possible between the individual machining processes. Witzig & Frank can offer them a complete solution in which several technologies are integrated into one machine. This offers our customers the advantage that components can be completely machined in large quantities on one machine and, if possible, in a single clamping process." Witzig & Frank machines run with very short cycle times of between three and 30 seconds and can produce quantities ranging from 500,000 to one million parts.

Benefits at a glance:

- Machining of all four workpiece sides in a single clamping process.

- Protection against dirt ingress thanks to hermetic sealing.

- Low maintenance requirements due to oil filling. Manual lubrication is not necessary.

- No loose hose lines in the machining area, as the hydraulic lines for the clamping device are routed through the swivel unit.

- Highly accurate positioning of the angular position by locking the swivel angle via Hirth rings in the swivel unit.

- Swivel unit equipped with adjustable hydraulic end position damping for very fast swivel times.

- Centric clamping of the workpiece, therefore, no influence of raw part tolerances on the clamping position.

Automated processing of cross joints on round transfer machines

Production at the next level

Strengthened by the support of the FFG Group, Witzig & Frank's international activities are also being driven forward. Nils Huber, Sales Manager of FFG Werke GmbH at the Offenburg site, succeeded in securing an order from a Chinese company in 2015. Wanxiang is the name of the company, and it is one of the largest automotive suppliers in China. For Witzig & Frank, which resumed production of machines just two years ago, this is a remarkable success. Nils Huber says: "We have tried to specifically target customers in China and Asia in general who we know produce these high volumes. They are usually willing to invest in new technology to take their production to the next level." In concrete terms, this means saving on personnel costs and space while simultaneously increasing product quality and plant availability.

The component that Wanxiang produces approximately 60 million units of per year is the universal joint of a cardan drive in three different sizes. During a visit to the Chinese automotive supplier's production facility, Nils Huber saw that several individual milling, turning, and drilling machines were required to machine the workpieces, all of which had to be loaded manually. In this case, a rotary transfer machine offered many advantages for making production more effective and productive and for producing high quantities of the highest quality.

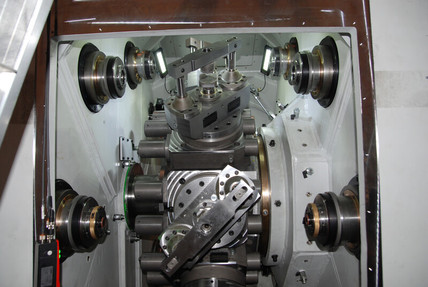

Witzig & Frank developed an eight-station rotary transfer machine of the LSA type for this purpose, on which the workpiece can be completely machined from all four sides. Like every machine produced by the Offenburg-based company, this system is also a customer solution that is delivered with workpiece-specific technology. To ensure that complete machining is reliable and precise, Witzig & Frank relies on reliable suppliers from whom it sources various components for its machines. The company has been relying on solutions from Röhm GmbH for the clamping systems for its machines for almost 40 years. The two companies are linked by a positive and now crossgenerational collaboration.

The Offenburg-based company has already installed more than 1,000 clamping solutions from the clamping technology specialist in its machines and has always strived to respond to customer requirements. Pascal Schnebelt explains: “The clamping device is one of the most important units in the machine. That's why it's particularly important to work with a reliable partner who can deliver the required quality.” Witzig & Frank found such a partner in Röhm.

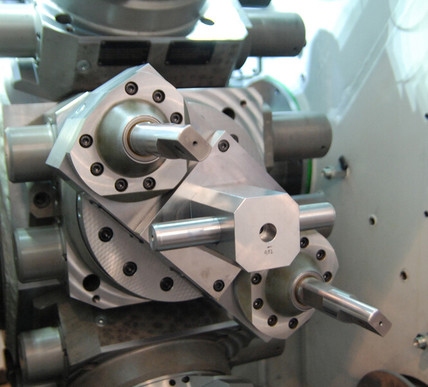

Witzig & Frank's machine concept posed new challenges for the clamping device. Since machining was to be carried out from four sides, an interesting clamping concept was developed in collaboration with Röhm. To clamp the yoke, not only did the open and close function have to be available, but it also had to include a kind of virtual W-axis that could be rotated exactly 90 degrees. The clamping device is mounted on a swivel unit from Röhm, which perfectly met the requirements. The clamping pressure of 45 bar was fed through the swivel unit. The advantage of the intelligent clamping device integrated into the machine concept was reflected in the part-to-park cycle times and in the compact design of the machine.

The production of universal joints is fully automated. Nils Huber explains how the process works: "The entire system is located within a protective fence. From the outside, the operator can drive a mesh box containing raw parts, weighing approximately one ton, into the system. From there, the system continues to work independently. A handling device tips the box onto a conveyor belt, the components are separated, and a camera system detects the position of the raw parts on the belt. This allows the robot to grasp a specific raw part. Since it has a double gripper, it can first remove the finished part from the machine and insert a new raw part for processing." The entire process of loading and unloading the machine takes place in nine-second cycles.

Reliable partner

A total of eight Röhm clamping devices and rotary tables are installed in the Witzig & Frank rotary transfer machine, as eight different stations can be processed within the system. In addition to milling, chuck turning, drilling, piloting, deep hole drilling, thread cutting, and turning, an eighth station even integrates a measuring process into the machine. At this station, any deviations can be reported back to the upstream turning station and the deviating dimension can be readjusted. A major advantage of the eight-station rotary transfer machine is that the workpiece to be machined remains firmly clamped at all times, thus preventing inaccuracy and saving time for reclamping.

Röhm GmbH provided Witzig & Frank with a high level of support in the field of clamping technology for this important international project. The collaboration in this case came about not least because of decades of positive experience with the clamping specialist. Pascal Schnebelt still remembers well the decision to choose Röhm: "At the time, we needed a complete package consisting of a rotary table in combination with the chuck for the rotary transfer machine. For us, the easiest way was to obtain this package from a single supplier. Of course, we are always under time pressure with projects like this, but Röhm's concept met all our requirements, and thanks to our long-standing partnership, we know that they will deliver the quality we need – and in a short time frame.“

Michael Schmitz, Technical Sales Manager Baden-Württemberg at Röhm, adds: ”At the time, I also campaigned vehemently for us to get this project. Ultimately, it is a combination of many factors that have to come together in order to implement such a system. But it is also important to have worked closely together during the tendering phase." The rotary transfer machine will be delivered to China at the beginning of this year. But it will not be the only system. Since Wanxiang manufactures approximately 60 million universal joints and the Witzig & Frank machine has a capacity of 2.8 to 2.9 million parts, follow-up projects could be in the pipeline for the Offenburg-based company and thus also for Röhm.

Contact

Do you have a special clamping task? Ask us!

Contact your

personal contact person

or write to us at

sales@roehm.biz