The Austrian EV Group relies on clever automation solutions on machining centers from Hermle for make-to-order production for their processing systems. At the heart of the systems are custom clamping systems from Röhm. The highlight is that a total of only eight clamping devices are needed for the highly varied range of parts. This saves not only space and costs, but on top, it reduces the maintenance expenses.

The EV Group, or EVG for short, is the leading manufacturer of processing equipment for wafer processing for the semiconductor industry, microsystem technologies, and nanotechnology. In a close working relationship with a global group of customers, EVG develops innovative systems for manufacturing micro- and nano-components. The product range includes lithography systems, wafer bonding systems, and inspection systems, which are manufactured at the company’s location in St. Florian am Inn. The company was founded in 1980 by Erich and Aya Maria Thallner. Today, customers include well-known companies such as, for example, Samsung, Sony and General Motors. “Today, our key competences are primarily in lithography and wafer bonding,” explains Herbert Tiefenböck, Corporate Operations Director at EV Group, and a specialist for the exciting manufacturing at EVG. Materials are processed, such as aluminum, brass, titanium, and also plastics such as PEEK. “Up to 70 percent of our machining involves cast aluminum" emphasizes Tiefenböck. The custom system builder has dealt intensively with the topic of unmanned production since the year 2000. “At that time, the opinion was that robot manufacturing was only for repetitive manufacturing,” says Tiefenböck. “In our opinion, this was a fallacy, because automation can also be realised in make-to-order production – assuming you define a common denominator for configuring such a system."

The fact that this concept works was already proven by EVG 17 years ago with the respective systems and a loader from Frei. When it became necessary to replace these systems, EVG got in touch with Hermle and Röhm a few years ago to develop a suitable solution. A system was to be created in which something called “vice workpieces” with the dimensions of 20 x 20 mm and a height of up to 150 mm up to a maximum of 200 x 200 mm can be machined in a system. “For commercial clamping systems, we discovered during our research that we needed 37 clamping devices for our range of parts, if we wanted to keep the projecting edges small,” says Tiefenböck. Considering the space required for this multitude of clamping devices in one loader cell, we had to look for another solution. “We then approached Röhm five years ago and inquired about suitable custom clamping devices,” explained Tiefenböck. The task was to supply a clamping device that is not sensitive to dirtying in the chip space, and is able to have the clamping force and opening width given via the machine tool. That is to say, definable via the controller. “The mechanics and control should be integrated in the machine table. In addition, it should be possible to quickly couple the clamping device and bring it to a starting dimension via a reference run and be controllable from that point,” says Tiefenböck as he gets to the heart of the requirements.

Stationary vice

Richard Schörkhuber, technical sales consultant with Röhm for Austria, who has supported EVG for many years, quickly had a suitable clamping solution ready together with Jens Papenfuß, the responsible design engineer at Röhm.

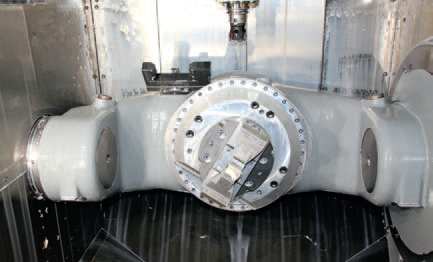

In the mechanical design, a stationary vice of the type SSP in conjunction with a zero-point clamping system, is coupled via a bevel shaft and bevel nut through which the movement can be controlled. There is then a reference run in the machine to define the fixed point. Then any clamping size can be approached that the clamping device provides. The vices are exchanged automatically by robots in order to cover the entire clamping range.

“Hence, we obtained a clamping device that is controllable by the machine tool, and with which we can cover our range of parts from 0 to 200 mm with eight clamping devices instead of 37. “With jaw movement of 30 mm and a clamping force of 2000 kg, this clamping solution is optimum for our production.”

After successful introduction of the automatic-mechanical clamping system on the Hermle machining centre C 30 U with robotic loading, Tiefenböck took this solution into consideration for systems with operators, especially considering the projecting edges. “The basis is once again a zero-point clamping system onto which the Röhm vice was swapped. Due to the optimum design of the clamping jaws, we also save ourselves many clamping device changes with this manual solution as well and can cover just as broad a parts spectrum as with the automated solution,” says Reinhard Lang, Manufacturing Team Leader at EVG, as he gets to the heart of the matter. Clamping is handled manually from the front with a conventional torque square socket wrench.

The vice from Röhm, with the jaw quick-change and Vprofile jaws with jaw movement of 30 mm, has a suitable large jaw movement and is optimally suited for the diverse range of parts at EVG. It is laterally flattened thereby providing a lot of free space for the tools on the Hermle machining centre. It also has a sealing air connector to prevent dirtying.

“In addition, we didn't want many different-sized clamping devices in order to cover the path from 20 x 20 mm parts to 200 x 200 mm workpieces,” says Tiefenböck as he describes the requirement. “We solved this through different jaw designs that are changed automatically by means of robots," explains Schörkhuber.

In another step, the jaw shapes were designed together with Röhm so that the shortest possible tool fittings could always be used over the entire range of parts, and could be operated up to the center of the workpiece. This is an important aspect, because that way the collision edges are kept very small. The jaws are also equipped with grips, which make mould clamping possible in addition to power clamping. “The grips grip onto the blank and result in positive clamping,” emphasises Tiefenböck.

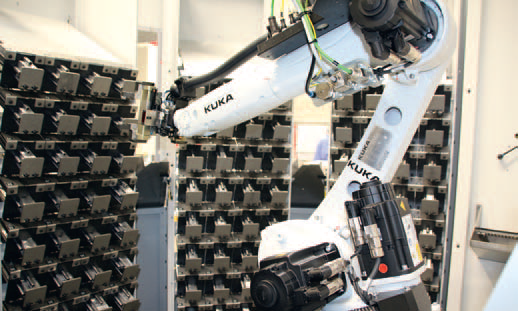

Another highlight in EVG’s manufacturing is a robot cell RS 05 with cell storage/Kanban from Hermle on a C 12 U. “180 different raw part sizes are maintained on the machine on our system day and night. Altogether, 4300 parts can be machined. In concrete terms, this means that the system can run through for around 15 days even with short runtimes of five to eight minutes per part,” explains Tiefenböck. “Mind you, without needing an operator to top up the raw material!”

High degree of flexibility

A hydraulically controlled vice from Röhm is used on this system, which can be operated exactly by means of volume flow metering. The benefit, in contrast to other clamping devices, which mostly only open or close completely, is the defined positioning of the clamping jaws via the hydraulics. In this way, the end face of the clamping jaws can be positioned exactly and insert the workpiece without it being able to fall through. Like the other solutions that Röhm developed for EVG, the benefits are the positive and non-positive clamping as well as the clamping force of 2000 kg.

Overall, the refined clamping technology solutions from Röhm have been more than worth it to EVG. The reduction of the clamping devices also means a high degree of flexibility for the large component diversity of the custom system builder. “Röhm won us over with its high level of expertise in project planning and the good quality as well as the very high accuracy of the clamping devices,” explains Tiefenböck in conclusion.