Clamping Device Solution facilitates Automation Process

Berlin is always worth a trip. This is particularly true for a visit to Siemens Energy – a corporation that is an international leader in energy technology. Created as a spin-off from Siemens AG in 2020, the company develops and manufactures a wide range of energy supply solutions. From conventional technology such as gas and steam turbines, generators, and transformers through technical solutions for sustainable energy. For an automation project at a site in Germany’s capital city, Siemens Energy utilized the products and services offered by clamping and gripping equipment specialist Röhm, based in Sontheim a.d. Brenz.

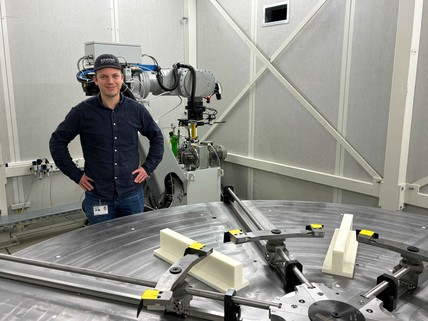

The Berlin facility focuses on further development of global energy technologies and the realization of sustainable energy projects. In this context, gas and steam turbines plus additional technologies play a key role. “This project related to one of the robot-based applications in our turbine production, which are still relatively rare,” says Markus Zapke, a team leader in the equipment, tooling and processes segment, when introducing the case study. “This application relates to milling of compressor guide rings for power plant turbines. We needed a universal, automated, flexible clamping solution.”

Matthias Barth, sales engineer and specialist adviser at Röhm, adds, “For many years now, Siemens Energy Berlin has been using a wide range of our clamping devices on a variety of machines.” Zapke confirms, “For decades now, we have been opting for Röhm clamping devices when purchasing and refitting machines. Röhm is a proven, well-known brand for our manufacturing facilities.”

Starting Situation

When searching for a solution, the initial idea was for a smaller competitor in the specialized machine segment to develop the clamping system. Nevertheless, from the start Röhm was the preferred expert for non-rivaling clamping solutions because they also pro-actively offered customized solutions. What was the specific task? The customer was looking for – and subsequently also introduced – a customized, hydraulically operated clamping system for the low-impact, reliable set-up of turbine rider rings. Until that point, there were no comparable “competitor chucks” within the manufacturing process, so competitors were also invited to submit quotations within the scope of the tender process. In the end, Röhm was awarded the contract. The reason for this decision is explained below.

Before the chuck was supplied, Siemens Energy had a manual labor station for the milling process, which has now been automated. The surrounding environment is very noisy, so the work station is located in an acoustic protection booth and the operative has to wear a hearing protection device. In addition to this, the task is physically very demanding and similar to working with a jackhammer. Siemens Energy’s industrial safety department therefore demanded changes in this work area. “The previous manual clamping solution was, above all, dependent on the operative’s ‘feel’ for the job,” says Barth when giving more details. “Now, they are primarily responsible for inserting the component; the technical solution handles the rest.” This ensures that the employee’s health, which is priceless, is protected. Noise emissions and physical overexertion are now things of the past. Zapke adds, “Further decisive advantages of the system are, on the one hand, that it now makes it possible to clamp a variety of rider rings from our entire portfolio. On the other, we have a time saving of about ten minutes per component. Another thing to mention,” says the team leader, giving Matthias Barth a meaningful look, “is that it might not yet have been possible to take all future design variations of our products into consideration, so we could possibly need to make further modifications in the future.”

Process Trigger and Production Process

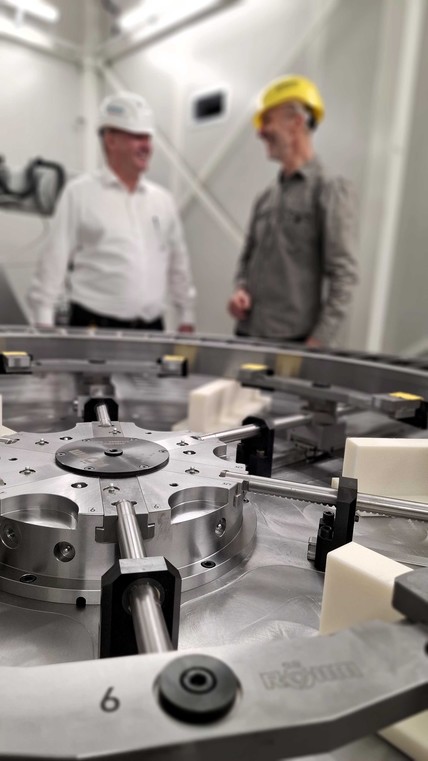

How did it all begin? The first contact was on December 6, 2022, when the responsible planner at Siemens Energy Tim Brückmann, sent an email to Röhm. It was followed by a number of phone calls and visits to obtain a more precise definition of the requirements. They included clamping the component to the machine bench; repetitive accuracy of concentric positioning of the component; incorporation of various diameters and component inner rings with different heights; no distortion of the components by clamping or process forces; clamping of separated components; preventing changes of position (twisting, shifting, lifting); use of the existing bench and its substructure; communication between the lifting and clamping systems; loading of the system from above; sufficient space for the rider ring including the lifting device / lifting tackle; accessibility of the inner ring’s outer diameter for the tool; compliance with EHS requirements (EHS = industrial safety); simple handling; a robust process; low maintenance; and easy replaceability of the clamping elements. “Multiple possible solutions were developed and discussed until we identified the current one as the optimum option,” remembers Markus Zapke. Barth adds, “Röhm received the order in July 2024 and the clamping system was delivered in early 2025.” Dennis Wolf, responsible for introducing robot-based machining solutions at Siemens Energy, followed the project, also getting hands on. Today, the clamping system is fully functional and further optimization is taking place.

A typical production cycle includes placing the component in the clamping system, followed by ‘rough’ alignment. After this, hydraulic clamping takes place and the milling process is carried. When milling has been completed, the component is released and removed from the clamping system. “The robot-based main process delivers the greatest impact,” says Zapke.

What Difficulties were encountered?

Every project has bumpy phases. Hand on heart: when was a ‘special coordination discussion’ required? “From the customer’s point of view there was an initial hurdle because we did not share the same understanding regarding the scope of the project,” reveals Zapke. “In the beginning Röhm seemed to assume that all they had to do was deliver a clamping system; in other words, without integrating it into our overall production line or doing the start up. But we are turbine builders and don’t have the ability to do this. Put simply, it’s not in our wheelhouse. We were expecting the manufacturer to integrate the clamping system. For us, this issue was almost a deal breaker for the project. However, senior managers on both sides assisted us with communications, working together to achieve an optimum technical solution. This enabled us to reach a consensus and get all the partners back on board to find a solution. Our specialist partner for production facilities (Racontec) played a key role in this, providing us with support and, with Röhm’s help, integrating the clamping system into the line.”

Barth continues, “From a technical point of view, the base plate of the existing carrier system and the related total mass including the component that had to be accommodated were further challenges.” In the end, a Röhm service technician supervised the installation ‘on site’ in Berlin. No special training or briefing were required since Siemens employees had been involved in the project from Day One.

Summary from the Berlin Side

Siemens Energy has been using Röhm clamping devices for many years now, including independent chucks with diameters up to 2,000 mm. This was the reason why planner Tim Brückmann contacted Röhm on December 6, 2022 to inquire about a solution for the task of “clamping large rings and ring segments with diameters between 1,500 and 2,500 mm”. His report started with a ‘wish list’. Following a number of discussions, the customized KFG300/3/6 clamping solution was identified as meeting most of the customer’s wishes. In summer 2024 Siemens Energy confirmed the order. Following this, Röhm developed and manufactured the solution, which was customized to carry out the task. In January 2025, the company delivered the clamping system and it was installed in February with the support of Röhm’s service unit. Today, Dennis Wolf of Siemens Energy is primarily responsible for ensuring that the system operates smoothly.

The collaborative project is a further example that a demanding, efficient, highly precise manufacturing process requires an equally efficient component set-up. Processes that at first glance seem to be secondary can also play a major role in a project’s success. “Today, the existing system is perfectly equipped thanks to the customized clamping equipment that we procured,” sums up Markus Zapke with classic Berlin humor in a concluding statement. “Should we have similar requirements in the future, it is highly likely that we will reach out to Röhm again.”

Contact

Do you have a special clamping task? Ask us!

Contact your

personal contact person

or write to us at

sales@roehm.biz