Flexible connection, optimum accessibility, precise machining, easy handling.

The RVM is a manually mechanically operated vice without power transmission for clamping all common materials.

Its solid yet slim design offers very high stability and accessibility. It is suitable for five-axis machining of a wide variety of workpieces in just one clamping. The RVM can be used in all common milling machines. It is designed as an eccentric vice.

https://www.youtube-nocookie.com/embed/q3S9OV6CUsA

We need your consent to load the YouTube video service. By accessing the YouTube-video, your personal data will be transmitted to the platform operator and third countries. Further information on this can be found in our privacy policy.

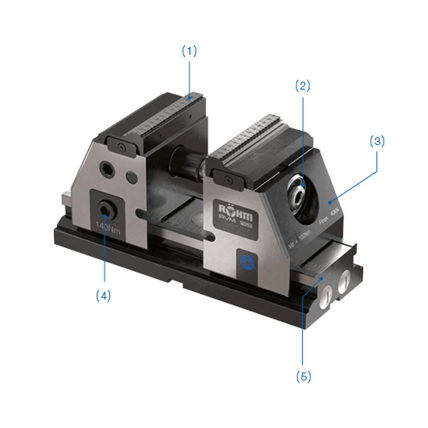

- Top clamping jaws with Jaw quick-change geometry

- Bearing-supported spindle for clamping force generation

- Solid yet slim base jaws for minimal interfering contour

- Central clamping screw for loosening and locking of the fixed base jaw

- Base body with scale for adjustment and pre-positioning of the fixed base jaw

- Easy-to-clean open design

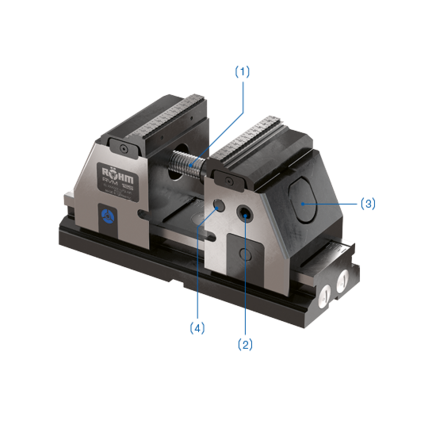

- Quick-release lock for loosening the spindle sleeve

- Threaded sleeve - forms the power clamping unit in conjunction with the spindle

- Threaded hole for screwable workpiece stop

Flexible connection to machine table

- with screws through the base rail (alignment via keyways possible)

- via zero point clamping system (for EasyLock Ø25/M12)

- by means of clamping claws on the outer contour of the rail (alignment possible via keyways). Rail lengths suitable for zero point clamping systems with support plate 350x350mm.

and workpiece

- Quick jaw change system for jaw change within seconds

- Very large clamping range for machining workpieces of various sizes and geometries

Ideal accessibility due to low interference contour

- Tool-optimised design: short clamping tools can be used; thus longer tool life possible due to low vibrations

- Optimum chip flow- Low overall height

Precise machining

- transfers accuracy of the machine to the workpiece

- Only one clamping, as machining operations on the workpiece can be reduced

- High clamping force up to 80kN total and 40kN per jaw

Easy handling

- Freely positionable clamping centre due to simple traversability on the base rail

- Quick clamping range adjustment through jaw quick-change system reduces set-up times

- Very large clamping range up to 195mm for machining workpieces of various sizes and geometries

- Quick changeover due to quick clamping screw and dimensional scale

- Same key for clamping and operation and thus only one tool required for operation

- Quick release bolt for spindle sleeve

- Easy to clean