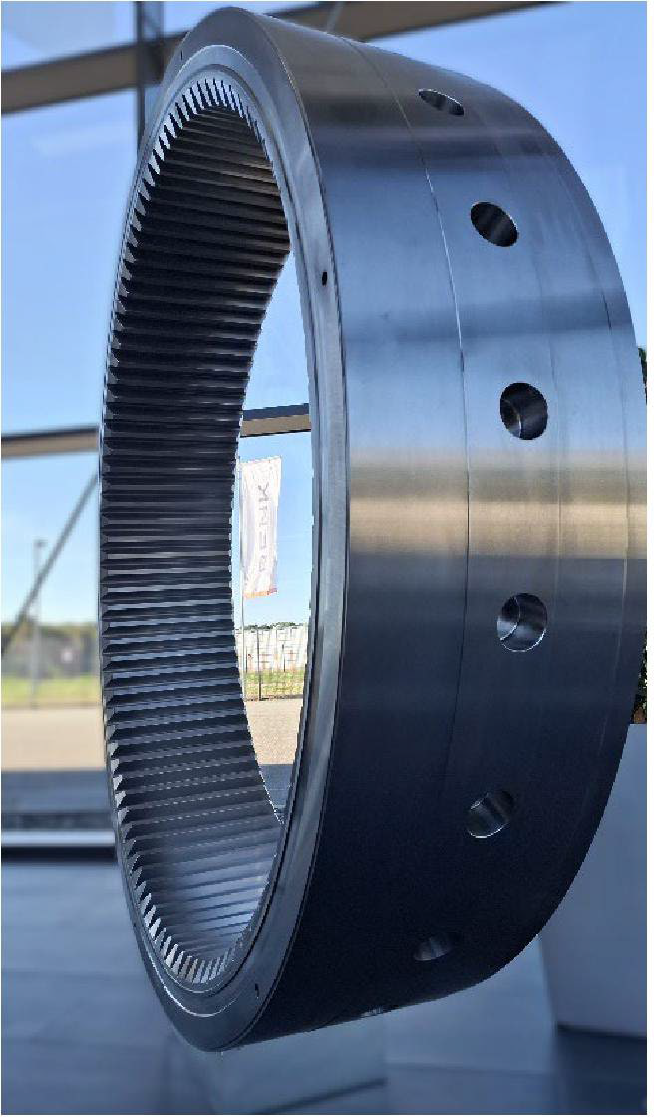

RENK Rheine supplies renowned customers in the energy generation, oil and gas, steel, and marine technology industries. Its products include marine propulsion systems, couplings, turbo gearboxes, and industrial gearboxes. High-quality clamping devices were needed to manufacture various components even more precisely, quickly, and with fewer changeovers. Those responsible found what they were looking for at Röhm, a clamping and gripping device specialist based in Sontheim a.d. Brenz

With over 430 employees, the Rheine plant is the second-largest location of the RENK Group after its headquarters in Augsburg. Anchored in the “Marine Industry” segment, Rheine specializes in the production of gear and clutch solutions for customers worldwide. The plant in Rheine was established in 1986 when the “Industrial and Marine Gear Units” product division was spun off from Augsburg into RENK-TACKE GmbH. In 1996, the TACKE shares were completely taken over. Since then, drive technology has been developed and manufactured for a wide variety of industries and applications. RENK Rheine supplies well-known customers in the energy generation, oil & gas, steel industry, and marine technology sectors, among others. RENK is currently manufacturing the world's largest coupling for a test bench for wind turbines in South Korea. An even larger coupling is already in the order book.

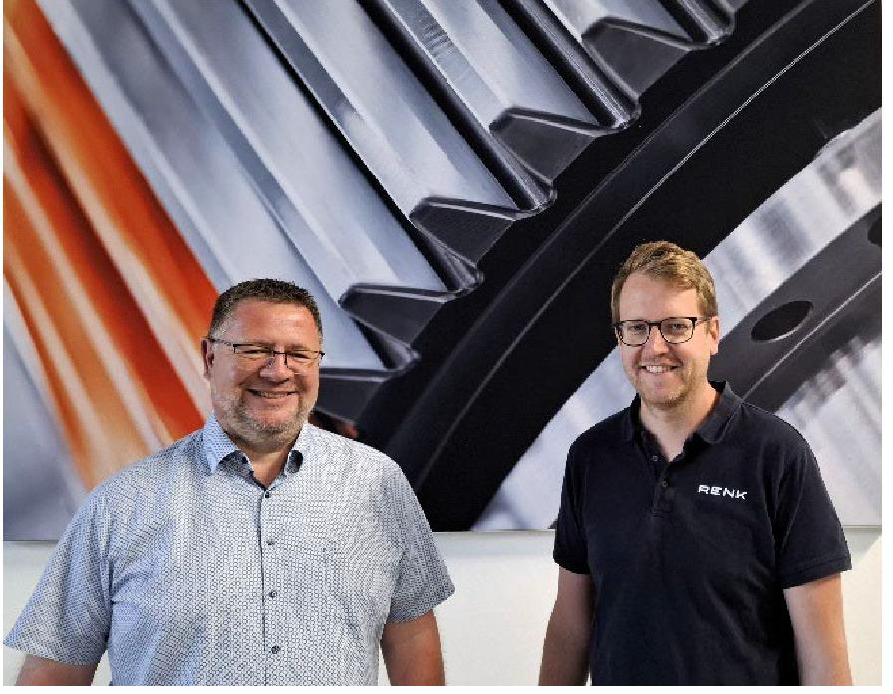

The RENK plant in Rheine and the clamping device specialist Röhm have been working together for more than 15 years. Since then, a wide variety of product groups have been ordered: from face plates, center points, and clamping jaws – all in both standard and custom designs – to manual and power chucks as well as vices. “Röhm has also been a reliable supplier of all kinds of clamping options at other locations for many years,” reports Carsten Jaeger, Production Foreman – Mechanical Production / MI-ORFN at RENK.

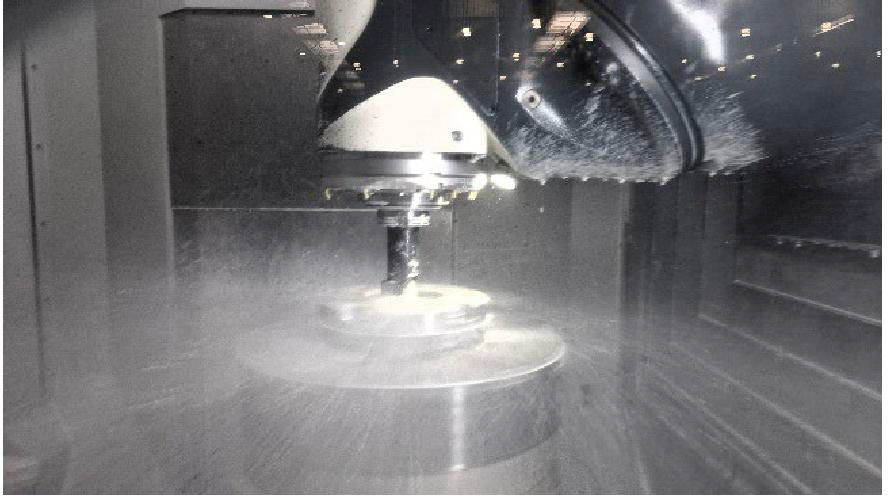

A current project involves hydraulic chucks, which Röhm delivered to Rheine in 2024, with a dozen units now in use. The chucks are fed to the respective machines in a linked production line consisting of three machine tools by means of a pallet warehouse. Before this happens, the chucks are loaded with workpieces at an external setup station and stored again in the pallet warehouse. RENK's requirements for the machining process and the chucks were primarily the highest possible centering and concentricity accuracy. “In addition, our goal was to make the system compatible for the future, for example, for loading with a robot,” adds Jaeger. “This solution now fulfills everything – and is particularly future-oriented with clamping devices that offer extremely high accuracy.”

Expandable and secure

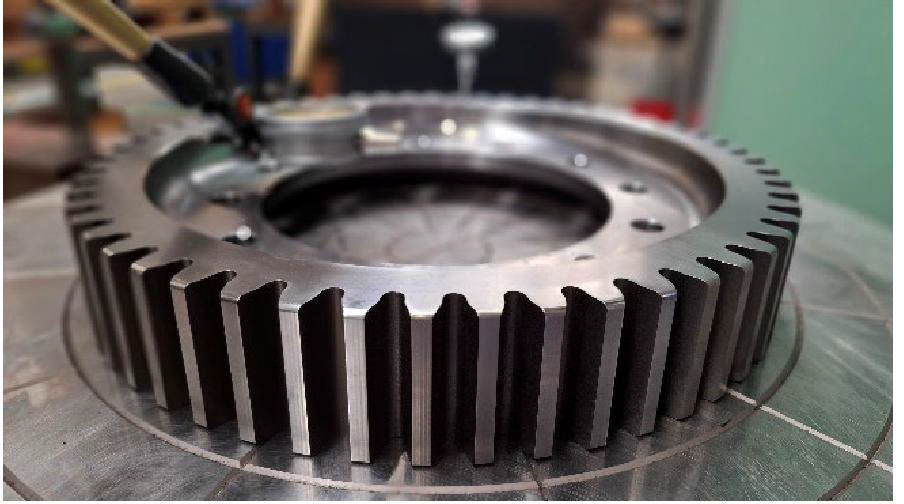

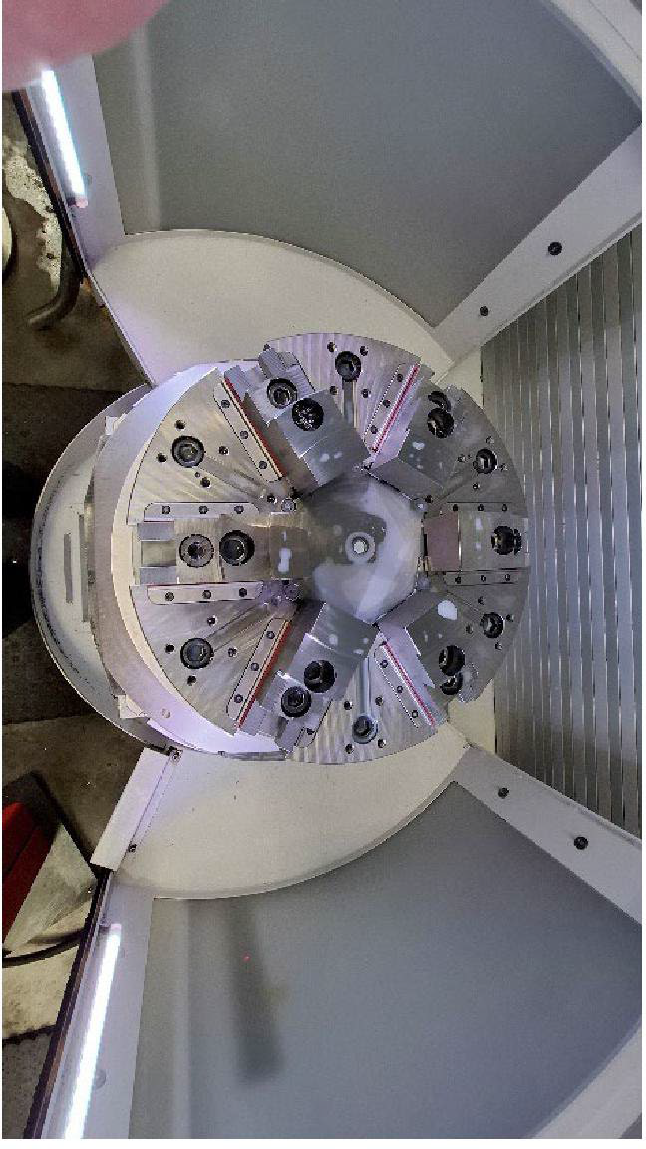

In this case, it was not a matter of replacing existing products, but rather of finding the “most suitable clamping device for this project.” Specifically, a total of seven KFG power chucks (diameter: 400 mm and 630 mm with six clamping jaws (1/16" x 90° serration) are now in use. The serration allows the clamping jaws to be adjusted radially to different workpiece and clamping diameters. The 3 x 2 jaw pairs clamp centrally and evenly to distribute the clamping force evenly, ensure central clamping during machining, and compensate for workpiece unevenness. When the next production machine was added during the course of the project, five more power chucks of the same design were ordered – a sign that the process is “running smoothly.” Another module is currently on order.

Our system is deliberately designed to be flexible, so the number of production machines can be expanded individually,“ Jaeger continues. ”In addition, our goal remains to equip the system with a robot in the medium term. This will allow us to make productive use of the times when the machine storage is insufficient and the system is running empty. Our product portfolio may expand in the future, which will present new challenges, such as machining thin-walled components."

Process initiation and production description

In addition to classic single-part production, RENK also manufactures small series. “We needed a future-oriented solution for both,” says Jaeger. "First, we looked for a manufacturing system that would offer optimum efficiency in both cases. Then we looked for clamping devices that would give us maximum quality for our products with the highest requirements. Our initial goal was to manufacture our curved tooth coupling housings in two clamping operations on the production machine and to combine the machining steps – turning, drilling, reaming, thread cutting, and gear cutting. We succeeded! Today, we are able to manufacture these components in two clamping operations. Previously, this was done on at least three, and in some cases even four, machines. This is only possible with the chucks manufactured by Röhm, which offer us the necessary precision."

Benefits and support

“The components are clamped outside the machine. As a result, there are no nonproductive times for the clamping process during the actual production time,” emphasizes Röhm Sales Engineer Thorsten Nolte. "The chuck is centered on the pallet using pins, positioned using slotted blocks, and secured using screws and T-nuts. The workpieces are loaded into the chuck and temporarily stored on a shelf until production.“

”It is important that employees accept this system with conviction. In the past, our workers clamped the components with manual chucks ‘by feel and experience’. There was skepticism at first,“ recalls Jaeger, ”but after conducting tests and determining the clamping pressures for specific applications, people are now very reluctant to work with conventional chucks. Today, the production staff is enthusiastic and would not want to use any other system or even do without the new solution.“

”Training courses conducted by our Röhm service technicians during commissioning help users quickly come to terms with the mostly positive changes,“ says Nolte, speaking from his many years of experience. ”In addition, we are of course always available to provide advice should any problems arise." Jaeger confirms: “Röhm was available to us at all times from the beginning to the end of this project and provided us with excellent support.”

Typical production process

The employee receives the orders to be processed via the ERP system. Clamping devices, NC programs, tools, etc. are assigned to the order. “As described above, we can now turn, drill, and – very importantly – gear the components on our machining centers. This enables us to produce a standard curved gear housing from a raw part to a finished part in less than an hour. In the past, we needed at least three machines with up to five clamping operations to do this.”

Conclusion

It took just ten months from the initial inquiry to the delivery of seven special clamping devices. Today, RENK Rheine can produce a standard curved tooth housing from raw material to finished product in just one hour. Previously, this required several machines and “could easily take several days.” Now, the North Rhine-Westphalia-based company can fulfill its customers' orders in no time at all.

“All in all, it took a lot of courage to tackle such a project: from replacing the production machines to introducing the linear storage system and new clamping devices,” concludes Carsten Jaeger. "In summary, we can say that our courage was rewarded. With Röhm's clamping devices, we have not only taken a significant step toward greater competitiveness in the coupling sector. With the clamping devices supplied by Röhm, we are also able to support our rapidly growing business segment in Augsburg – here, the high precision of Röhm clamping devices is a huge advantage. With our company's growth strategy, we will certainly realize further projects together in the near future."

About Röhm GmbH:

Röhm GmbH, with its headquarters in Sontheim an der Brenz (Baden-Württemberg) and production sites in Dillingen (Bavaria) and St. Georgen (Black Forest), specializes in the development, design, and manufacture of high-precision, robust and durable clamping and gripping devices. The products are "Made in Germany." Röhm's clamping and gripping devices are used worldwide by almost all renowned manufacturers in the automotive industry, railroad technology, watches, medical technology, power engineering, as well as in woodworking. Röhm also manufactures special clamping devices and handling equipment for use in cleanrooms in accordance with cleanroom class ISO 7.

Röhm has its own subsidiaries in England, France, Italy, Switzerland, Spain, Poland, USA, China, and Mexico. Founded in 1909, the company quickly became known worldwide for its drill chucks. To this day, Röhm develops and manufactures drill chucks at the Sontheim location that are used worldwide by almost all manufacturers on stationary as well as handoperated electric tools for screwing and drilling.

www.roehm.biz