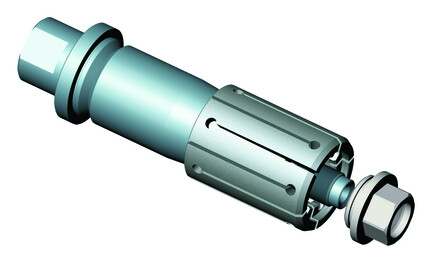

Cartridge mandrels, hand-operated

For manual, precision, internal clamping for turning, milling, grinding and gear cutting

The centric and comprehensive internal clamping of cartridge mandrels are particularly impressive for very small clamping diameters and at low overall heights.

Most manual-clamping cartridge mandrels from Röhm can be modified by an adapter to be force-actuated, i.e. automatically clamping cartridge mandrels.

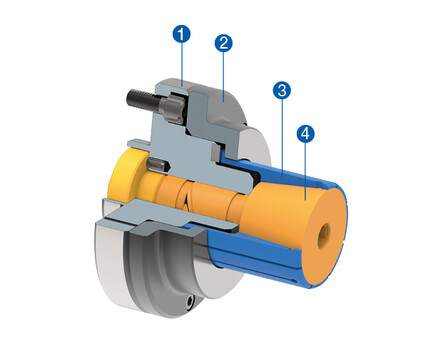

1: Low weight and reduced overall height due to compact construction

2: Workpiece stop for high axial true-running

3: Double-sided, slotted clamping sleeve for high concentricity

4: Elongation of the clamping sleeve via the clamping taper

MFS

Internal clamping with axial tightening of round workpieces for turning, milling, grinding and gear cutting as well as for balancing and measuring. Ideal for thin-walled and long workpieces or long clamping lengths

Clamping range: Ø 20.7 – 55.7.

MFR

Internal clamping without axial tightening of round workpieces for turning, milling, grinding and gear cutting as well as for balancing and measuring. Ideal for short clamping lengths or workpieces, bind holes, stepped holes

Clamping range: Ø 20.2 – 71.7

MZB

Internal clamping with axial tightening of round workpieces with very small clamping diameters for turning, milling, grinding and gear cutting as well as for balancing and measuring.

Clamping range: Ø 7.5 – 79.7

MZS with bearing collar and center holes

Internal clamping with axial tightening of round workpieces between centers for radial and axial run-out checking, turning, grinding, gear cutting

Clamping range: Ø14,7 – 100,7

MKS with tightening nut, morse taper

Internal clamping of round workpieces for turning, grinding, etc. as well as checking

Clamping range: Ø14,7 – 139,7

MKB with tightening nut and longitudinal stop, morse taper

Internal clamping of round workpieces for turning, grinding, etc. as well as checking

Clamping range: Ø5,5 – 78,7